Ceramic Tile Glazing Machine

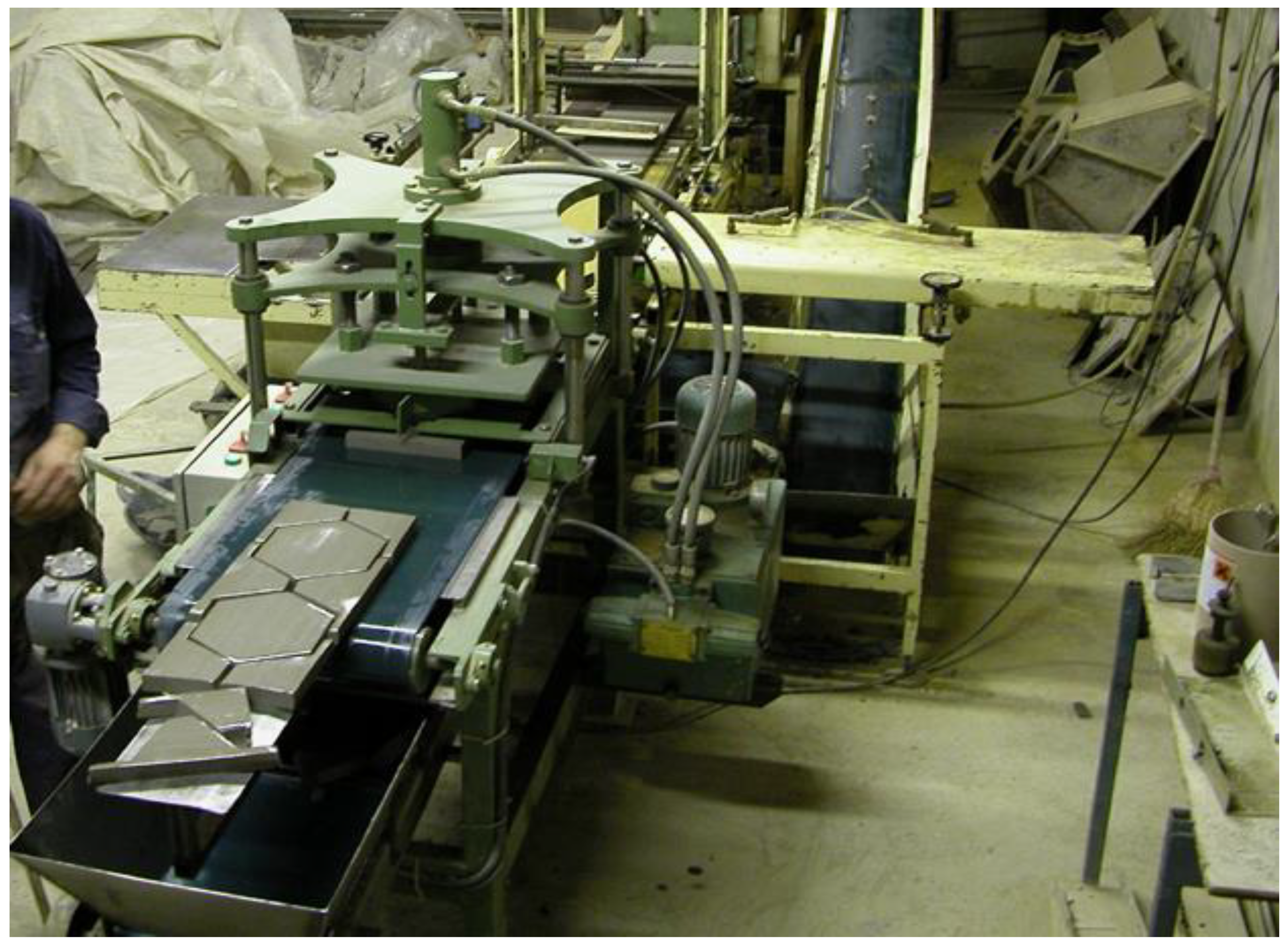

It is a latest generation cmc collector for collecting tiles coming from the press.

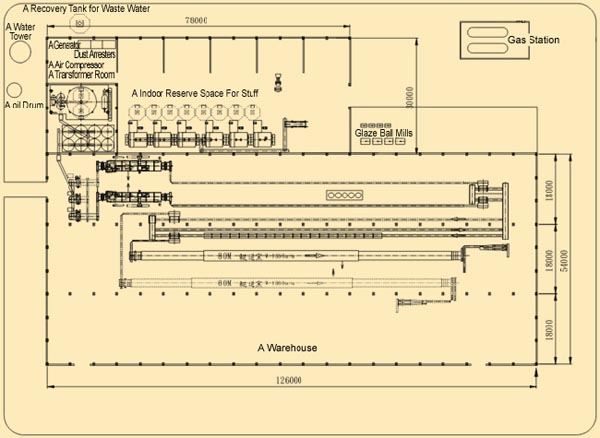

Ceramic tile glazing machine. You can also choose from double loading tiles vitrified tiles ceramics glaze machine as well as from 1000 x 1000mm 300 x 300mm and 600 x 600mm ceramics glaze machine and whether ceramics glaze machine is floor tiles accents or borders. Drying 5 ceramic tile usually must be dried at high relative humidity after forming especially if a wet method is used. You can also choose from roof floor ceramic tile glazing machine as well as. Designed for quick mould punch changeovers it is adaptable to all types of mould.

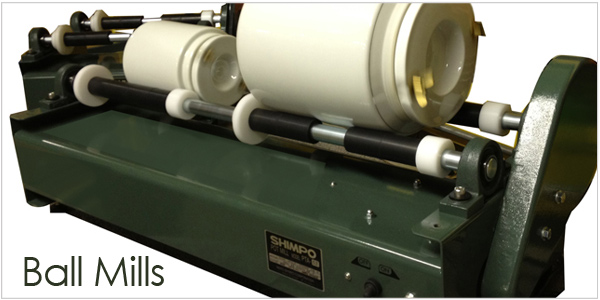

Advantages include the elimination of glazing lines as well as the glazing waste material called sludge that is produced with the conventional method. Jiffy mixers of all sizes sieves scoops whisks hydrometers and more. 39 0536 943403 vat. The beautiful glaze you see in ceramic tile is baked on in kilns at temperatures ranging from 900f to 2500f.

Refinishing is a much better option to replacing ceramic tile. Press integrated system available on wide clearance and high tonnage machines making the press highly flexible during size changeovers. Handling of fired products is done with automatic vehicles. 39 0536 940393 fax.

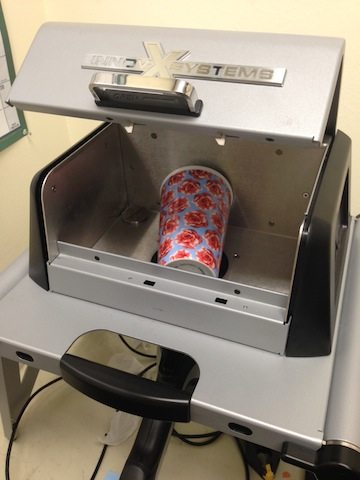

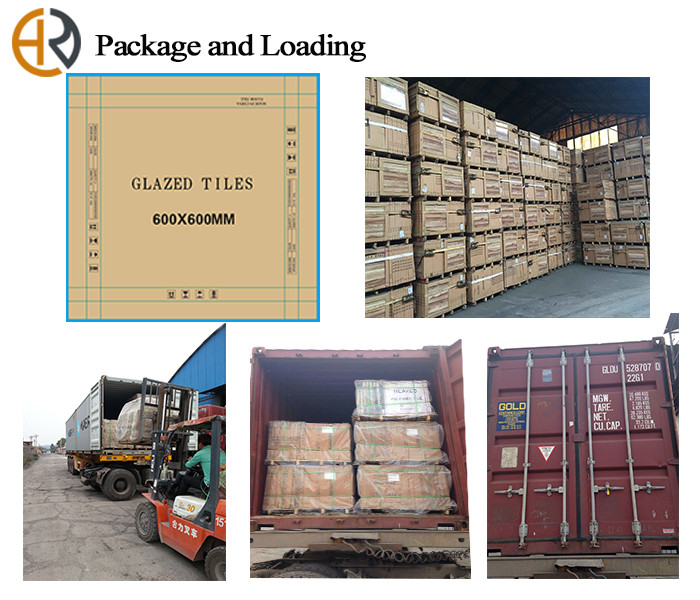

Sacmi offers a wide range of machines to sort through and package tiles and slabs. The glazetile project enabled companies sce and tecno italia to develop a novel family of digital machines that addresses the downsides of current inkjet printing for ceramic tile glazing and decoration. A wide variety of ceramic tile glazing machine options are available to you such as tile forming machine tile cutting machine. In the case of large size ceramic production a solution is available with intermediate storage of fired product and the subsequent surface finishing and format cutting depending on the job order.

A wide variety of ceramic glaze machine options are available to you such as plastic ceramic. The term tile reglazing is a misnomer as it is impractical to remove ceramic tile that has been installed and ship it back to the factory for re firing in a kiln. Glazing and decorating with water based inks.