Ceramic Tile Quality Testing

These factors determine the safety of the tile and its.

Ceramic tile quality testing. Inspection of second grade tile is done at a distance of ten feet. Ansi a137 1 2019 american national standards specifications for ceramic tile is a crucial compliance document for the ceramic tile industry. In this test method the bond strength between tile specimens and a mortar bed when bonded with portland cement paste is determined. The test method may be used to evaluate glazed ceramic wall tile ceramic mosaic tile quarry tile pressed floor tile and porcelain tile.

This method also includes both face mounted and back mounted tile. The astm c1368 10 test is used to determine the slow crack growth parameters of ceramics products by using a stress rate rectangular beam flexural testing. Tests on tiles transverse strength test on roofing tiles based on astm c 1167 and is the transverse strength test of roofing tile is commonly carried out based on the specifications of applicable standards such as astm 1167 11 and is 13801. The astm c1285 02 test methods evaluate the chemical durability of glass ceramics and multiphase glass ceramic waste forms by evaluating the concentrations of the chemicals released to a test solution.

Check the grade of the tile. Testing of ceramic floor and wall tiles for product conformity quality control safety performance and legislative reasons we offer testing of ceramic floor and wall tiles to a wide range of uk european and international standards in our ukas accredited testing laboratory no. Astm c1285 02. Sold as standard grade a ceramic tile passes a visual inspection for color consistency and warping at a distance of three feet.

Ceramic tiles are rated via the american society for testing and materials for their abilities to withstand normal use circumstances. To test this the fired tile is first weighed then it is boiled for five hours and left to sit in water for 24 hours. It involves wet or dry method test and conducted in the lab to estimate. The dimension should be as per actual size and tolerance should not exceed 1mm in length and breadth and tolerance should not exceed 3mm in thickness.

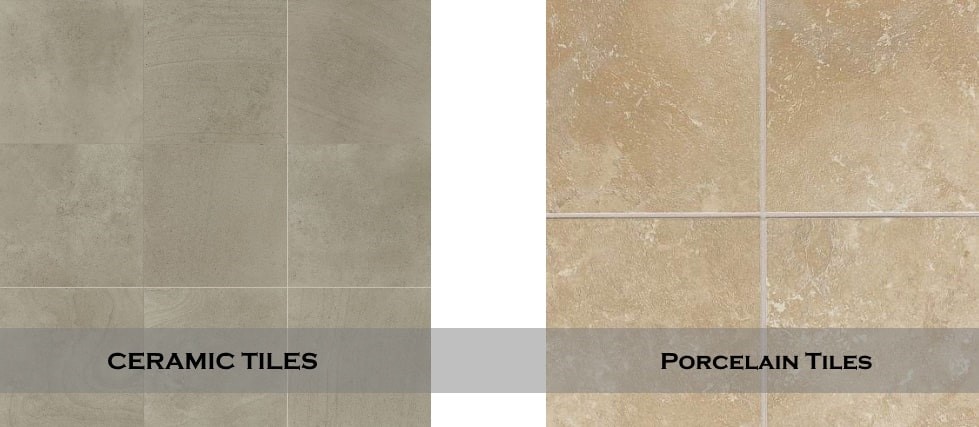

Astm c1368 10. At lucideon we test materials and products across the traditional and technical ceramics industries for raw material assessment product development and quality control as well as for product and material evaluation conformity safety legislative and environmental impact purposes and to ensure that products are fit for purpose. Best practice to check a glazed tiles non glazed tiles engobed tiles pressed tiles extruded tiles and cast tiles quality the size of ceramic tiles should be perfectly square or rectangular. Porcelain tile porcelain tile has a water absorption rate of 0 5 percent or lower as defined by the american society for testing and materials astm section c373.