Ceramic Vibration Control

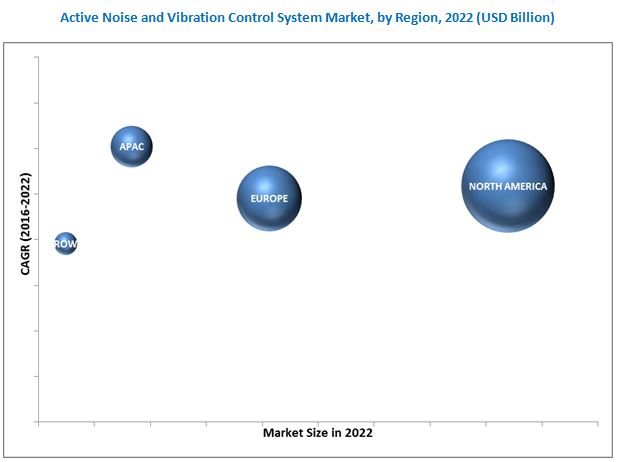

Ceramic carbon fiber seem to have improved cone performance over metal cones of the.

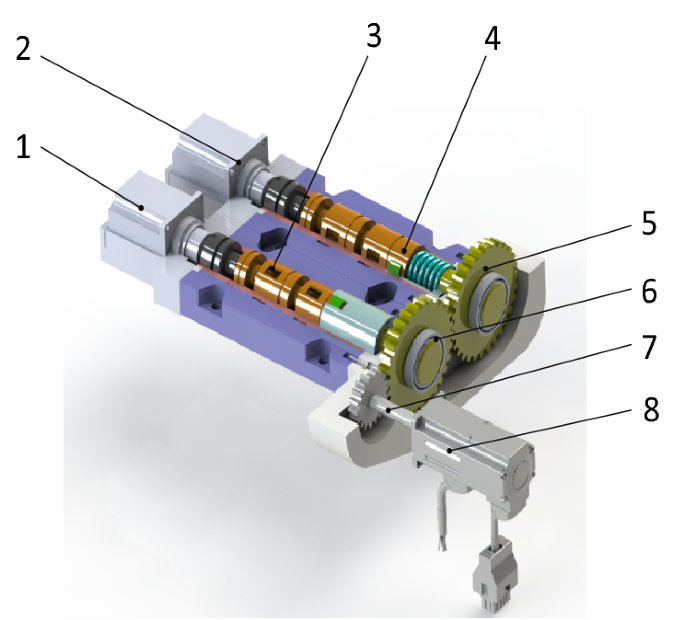

Ceramic vibration control. Vibration and noise control at the transmission and iii vibration and noise control at the fuselage. Accessories vibration control golden sound dh ceramic cones small 5 8 set of 3. Precision positioning valves switches vibration control etc. Understanding the many other options will help lead to the proper choice.

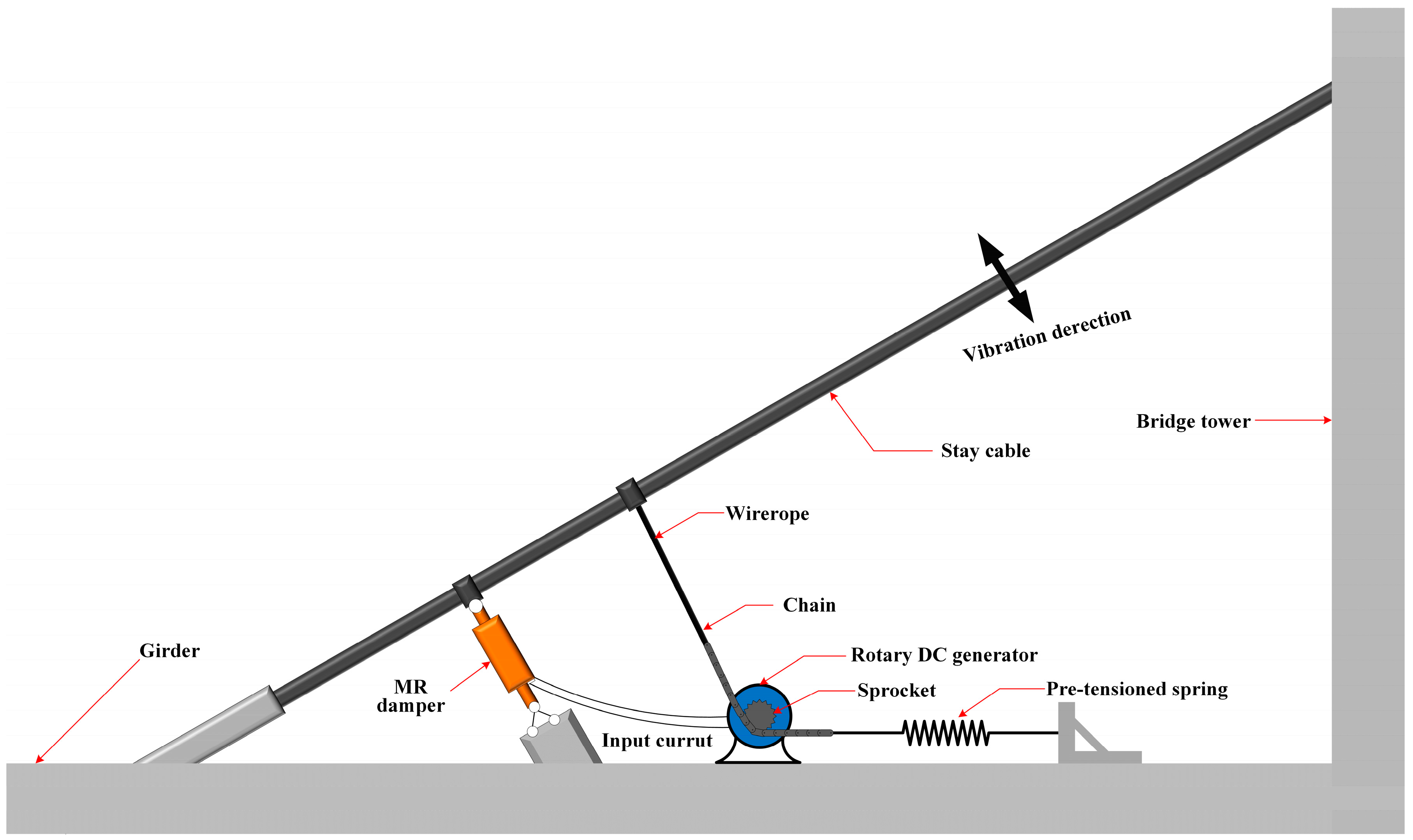

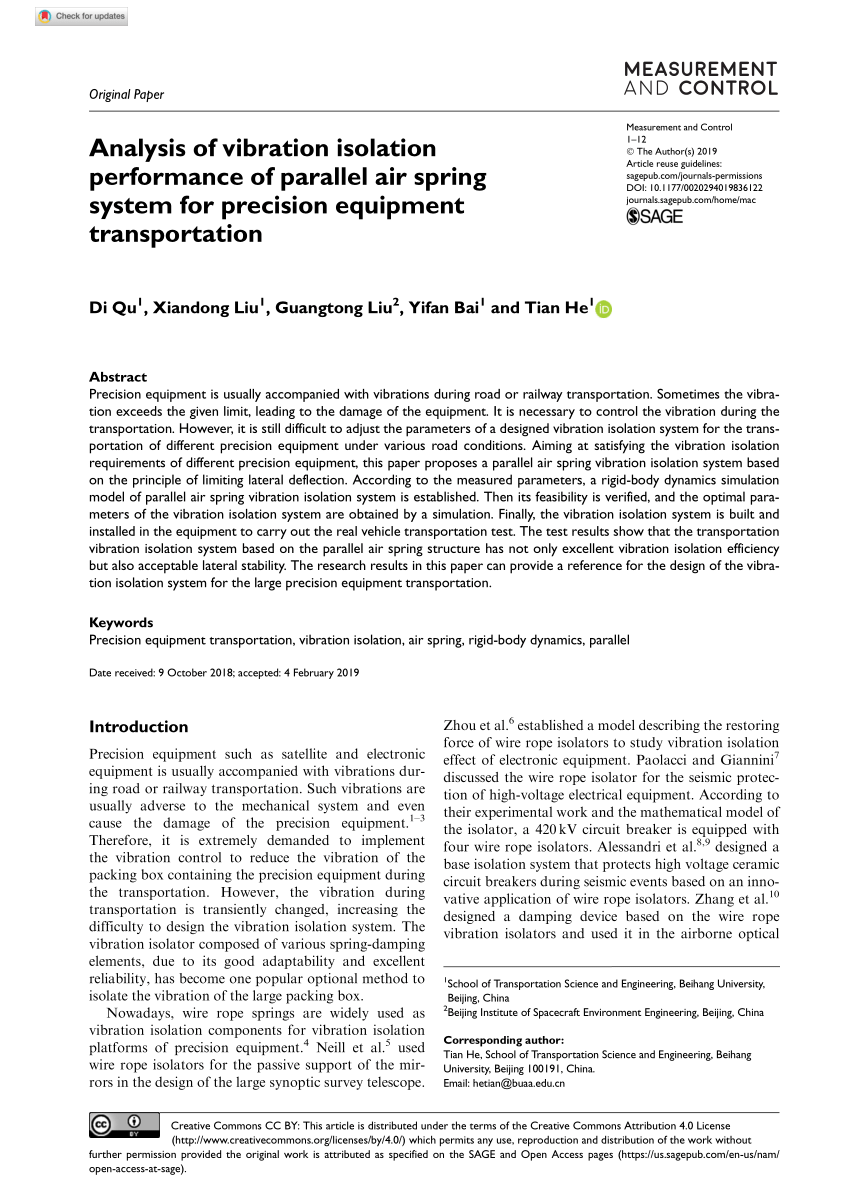

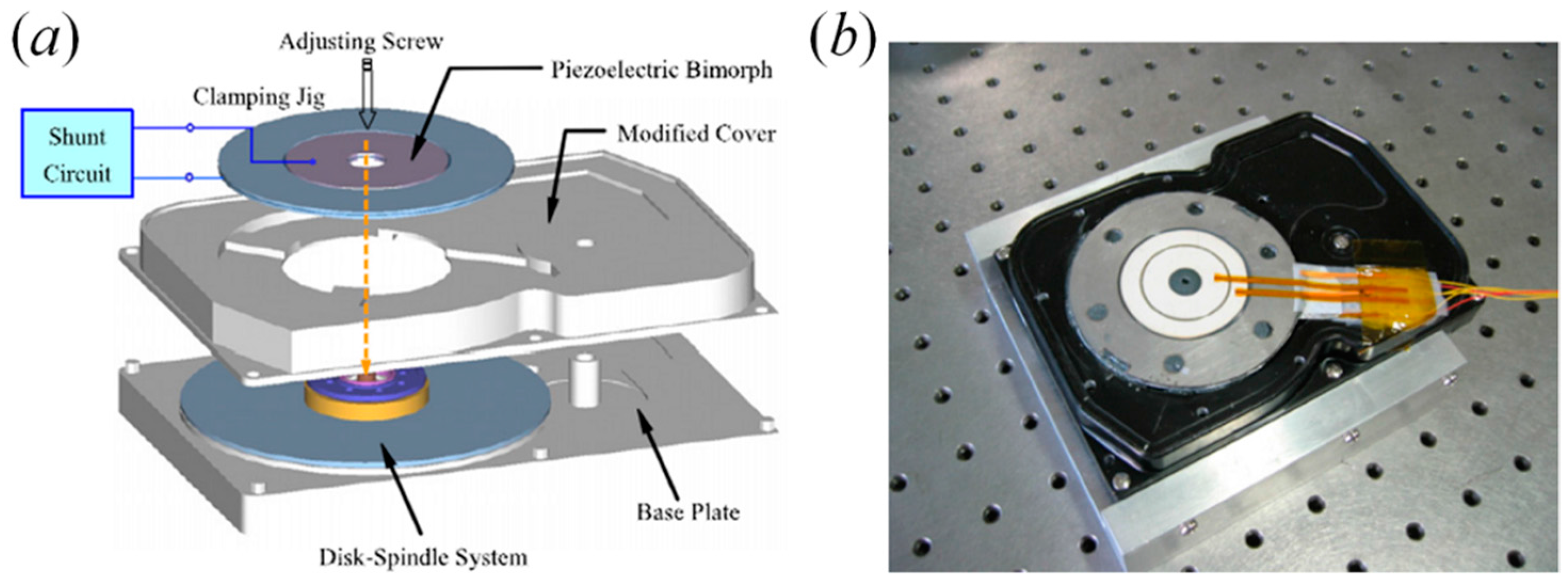

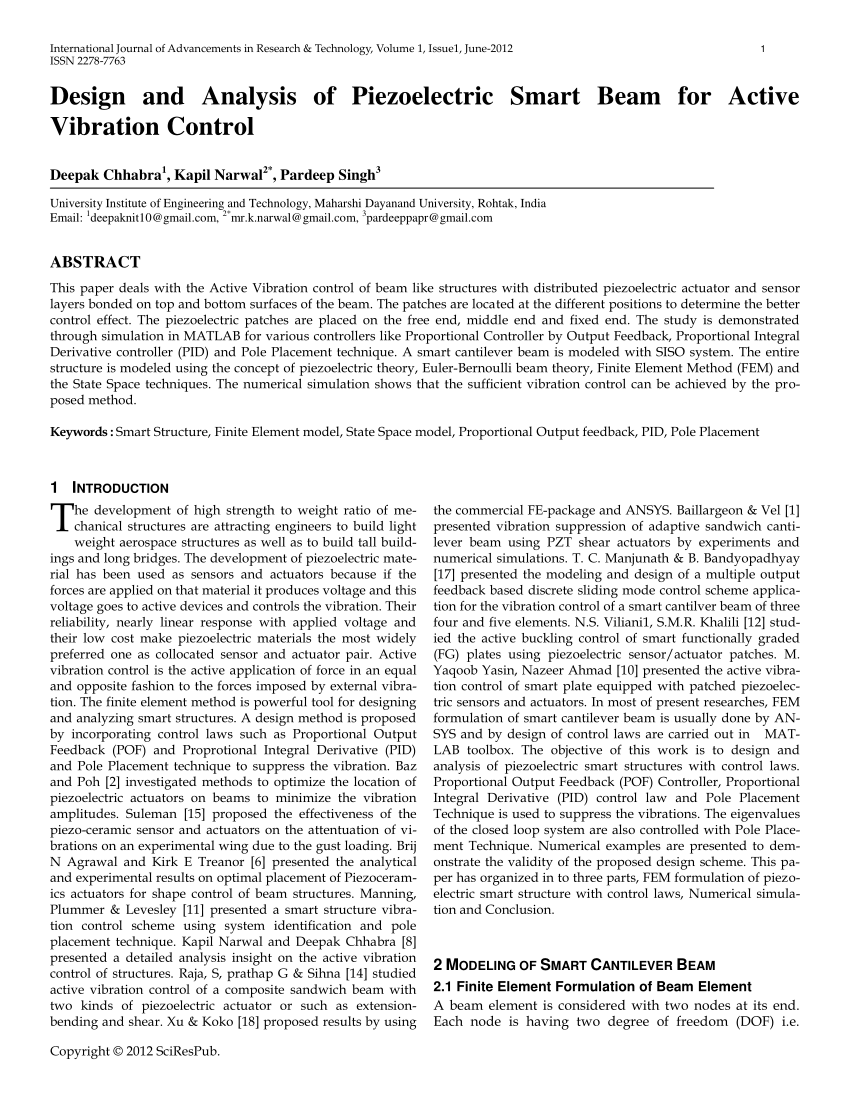

Comprises a dynamic vibration absorber with a metal plate of small mass that deals with higher frequency vibration while piezo ceramic comprises a shunt damper with an electric shunt circuit that works for lower frequency vibration. Lighter weight ceramic balls and dissimilar materials reduce the risk of false brinelling damage considerably. Omega manufactures piezoelectric ceramic components for a wide range of applications including sensors e g. Golden sound cones are extremely tough almost as hard as diamond but substantially less resonant allowing them to support.

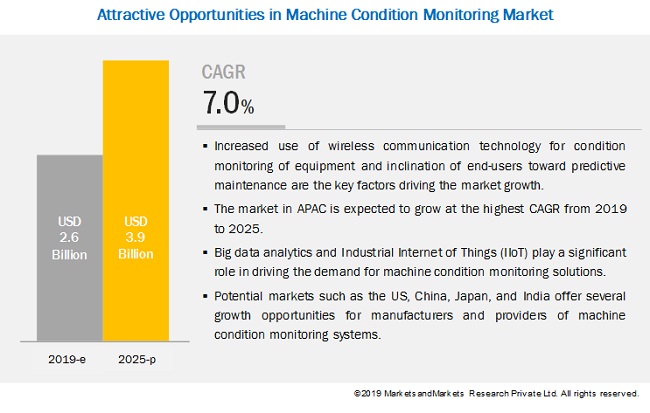

Choosing the right type of control system and form factor are only two of the many decisions to make when defining the right active isolation platform for the job. The piezoelectric ceramic composite ultrasonic transducer is simplified as a mechanical model of a composite thick wall tube composed of a. Equipment exposed to static vibration risks false brinelling erosion of the surfaces within the ball and raceway contacts which can lead to spalling and premature failure. The signal separation method.

Emphasis is placed on the reduction of rotor induced vibrations and noise which is still the key challenge in developing the jet smooth ride helicopter. Pressure vibration level acceleration flow etc transducers e g. 5 0 out of 5 stars 1. All golden sound cones are made of a high tech ceramic material so advanced it s used in the aerospace industry and by nasa.

All of us have seen attempts at vibration control. The main compositions and material. A piezoelectric self sensing actuator ssa can reduce the cost of the active vibration control system and simplify the stru cture by eliminating the use of a sensor because a ssa can have both actuating and sensing functions at the same time. 59 1 92 count get it as soon as thu may 14.

Different from the existing equivalent circuit analysis method of the transducer based on the vibration theory of the mechanical system and combined with the constitutive equation this paper analyzes the radial vibration characteristics of the transducer. The effectiveness of this approach is examined through vibration control of a can tilever beam. Medical ultrasound ndt ultrasonic cleaners and welders speakers and alarms etc and actuators e g. 1 introduction in the recent years new active noise and vibration systems utilizing.