Ceramic Vs Metal Stress Strain Curve

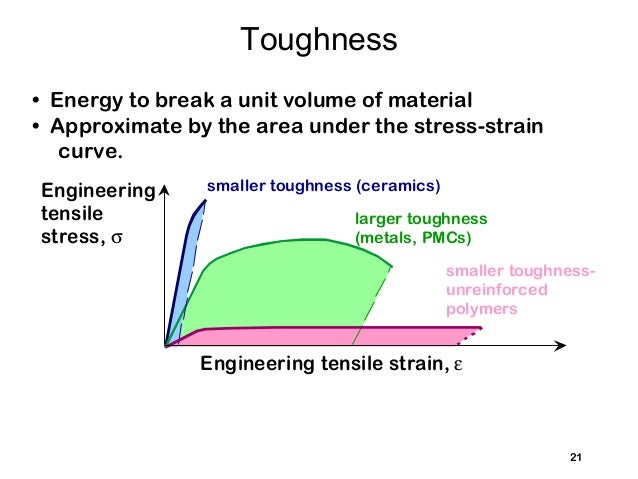

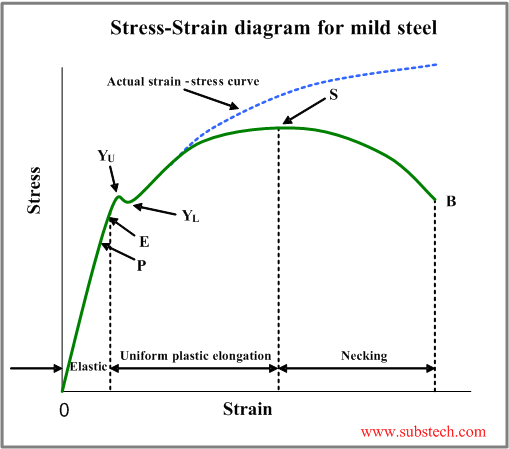

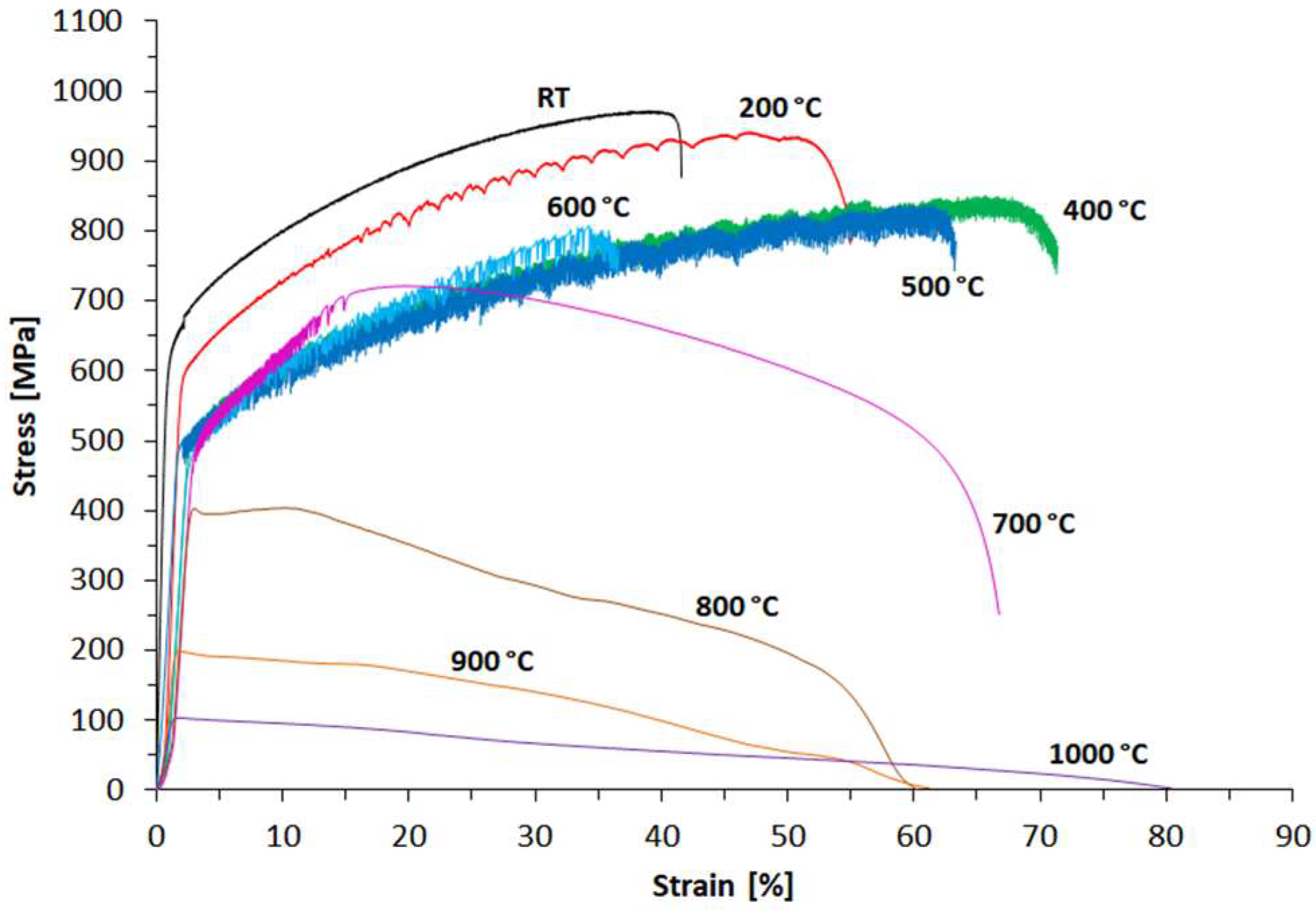

The parameters which are used to describe the stress strain curve of a metal are the tensile strength yield strength or yield point percent elongation and reduction of area.

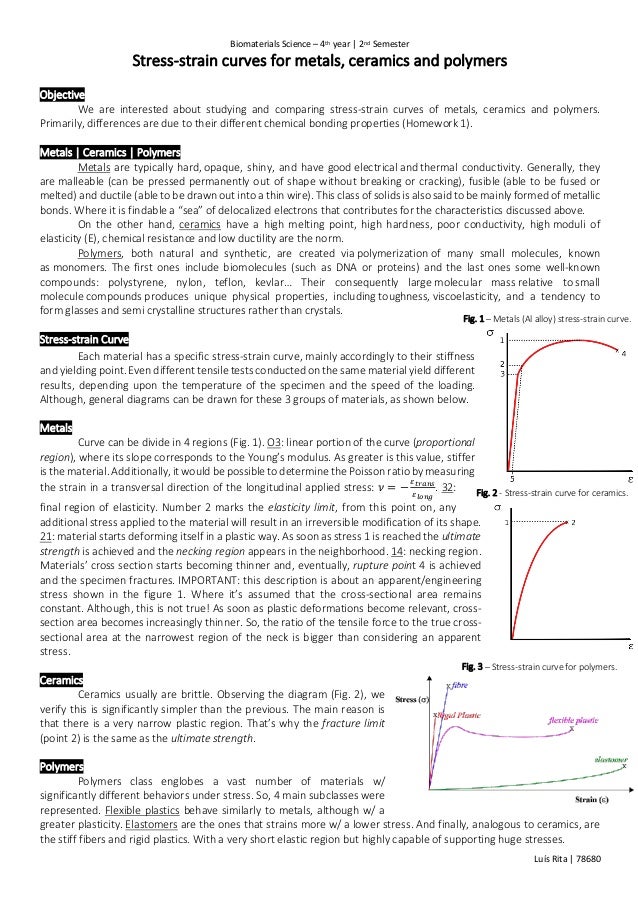

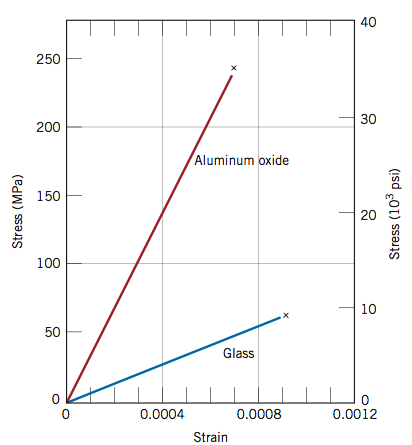

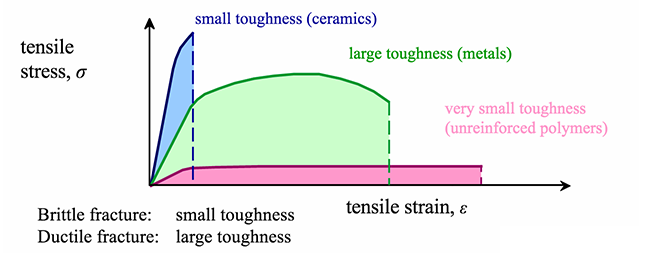

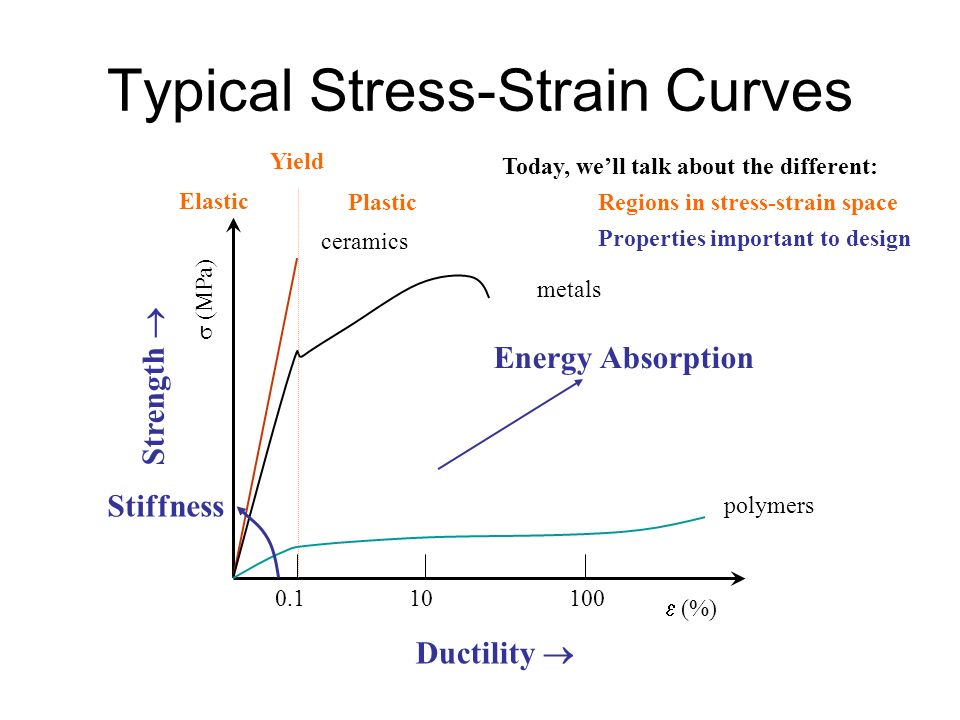

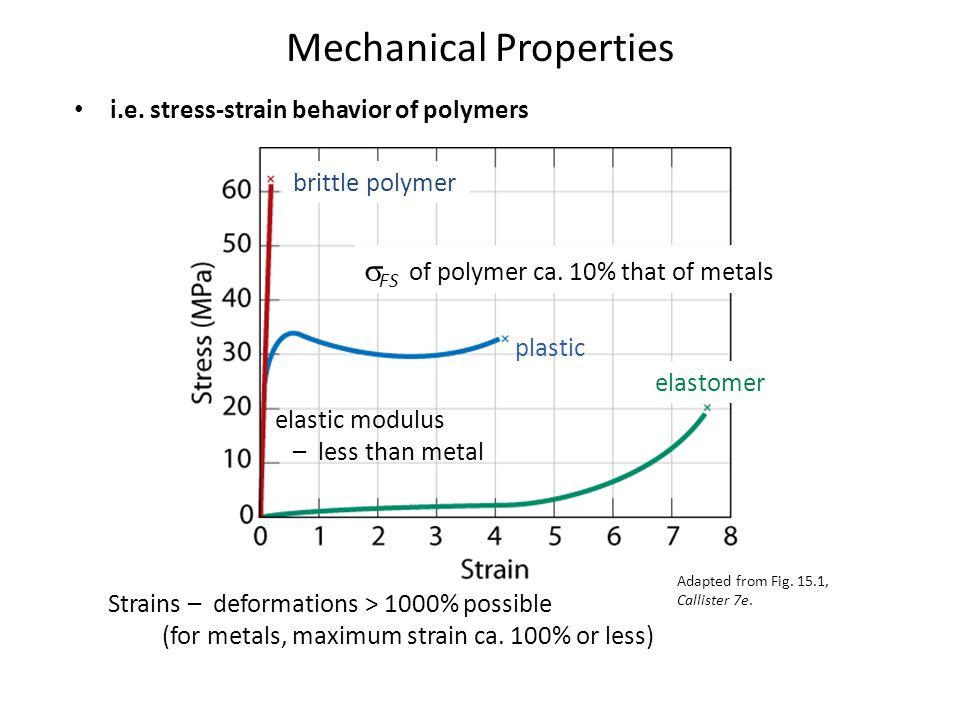

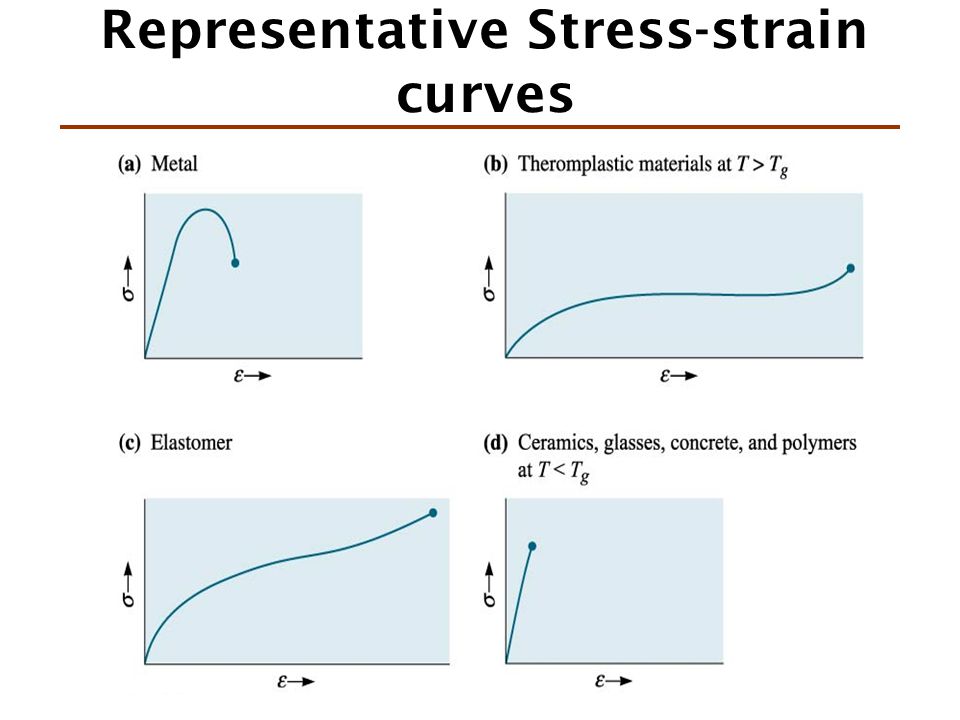

Ceramic vs metal stress strain curve. The zone where a material will return to its original shape for a given amount of stress toe region applies to a ligaments stress strain curve. 2 stress strain curve for ceramics. The stress at the maximum on the engineering stress strain curve metals. Occurs when crack propagation starts polymers.

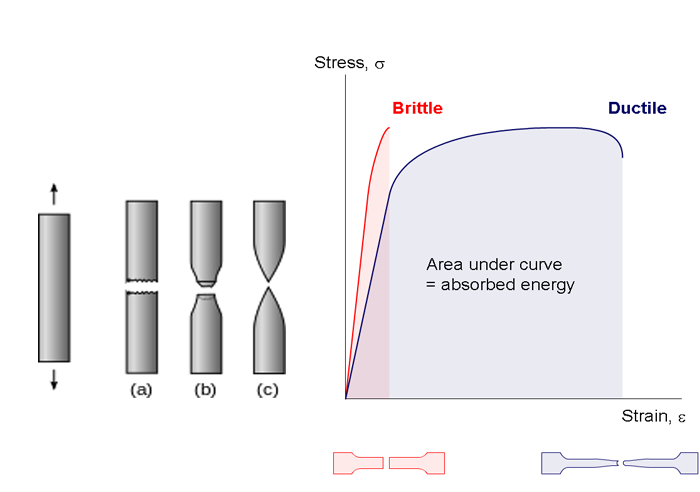

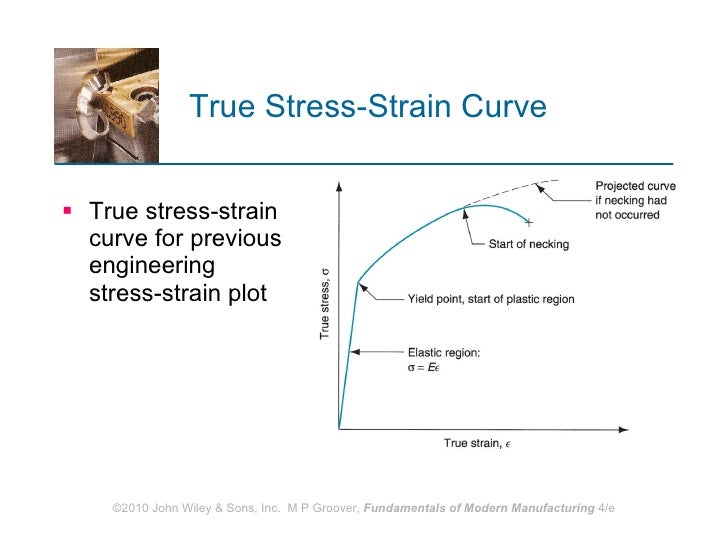

Occurs when noticeable necking starts ceramics. The general shape of the engineering stress strain curve fig. Derived from axially loading an object and plotting the stress verses strain curve. In engineering and materials science a stress strain curve for a material gives the relationship between stress and strain it is obtained by gradually applying load to a test coupon and measuring the deformation from which the stress and strain can be determined see tensile testing these curves reveal many of the properties of a material such as the young s modulus the yield strength.

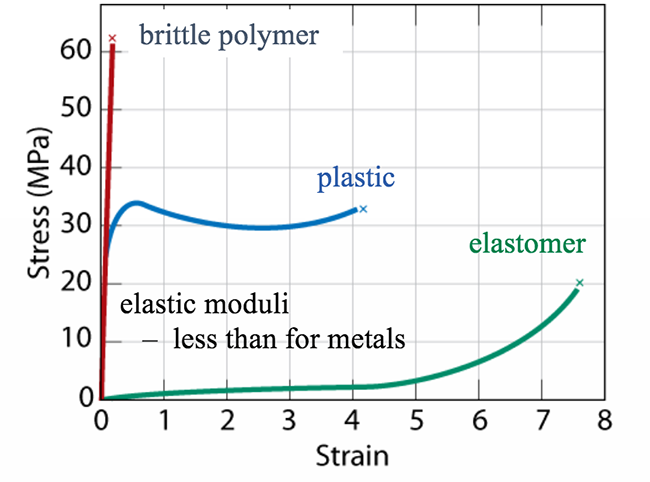

Occurs when polymer backbones are aligned and about to break σ y engineering typical response of a metal ts stress engineering strain. With a very short elastic region but highly capable of supporting huge stresses. Represents straightening of the crimped ligament fibrils. 1 requires further explanation.

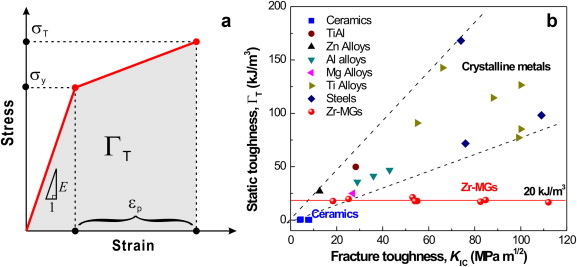

Elastomers are the ones that strains more w a lower stress. And finally analogous to ceramics are the stiff fibers and rigid plastics. The first two are strength parameters. Stress vs strain curve.