Ceramics And Refractories Ppt

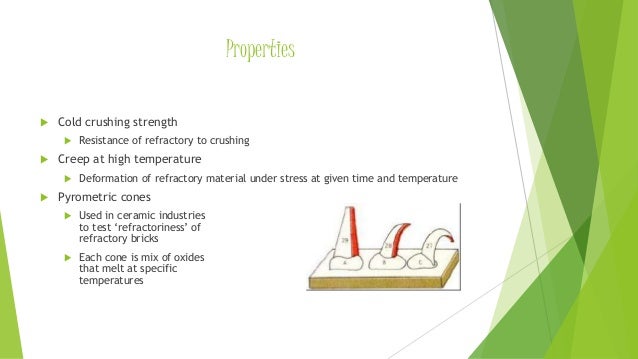

Test refractories under load test r u l.

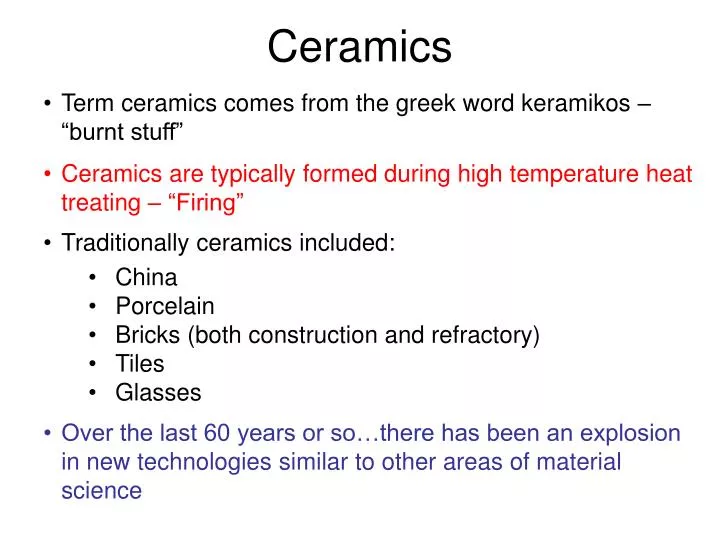

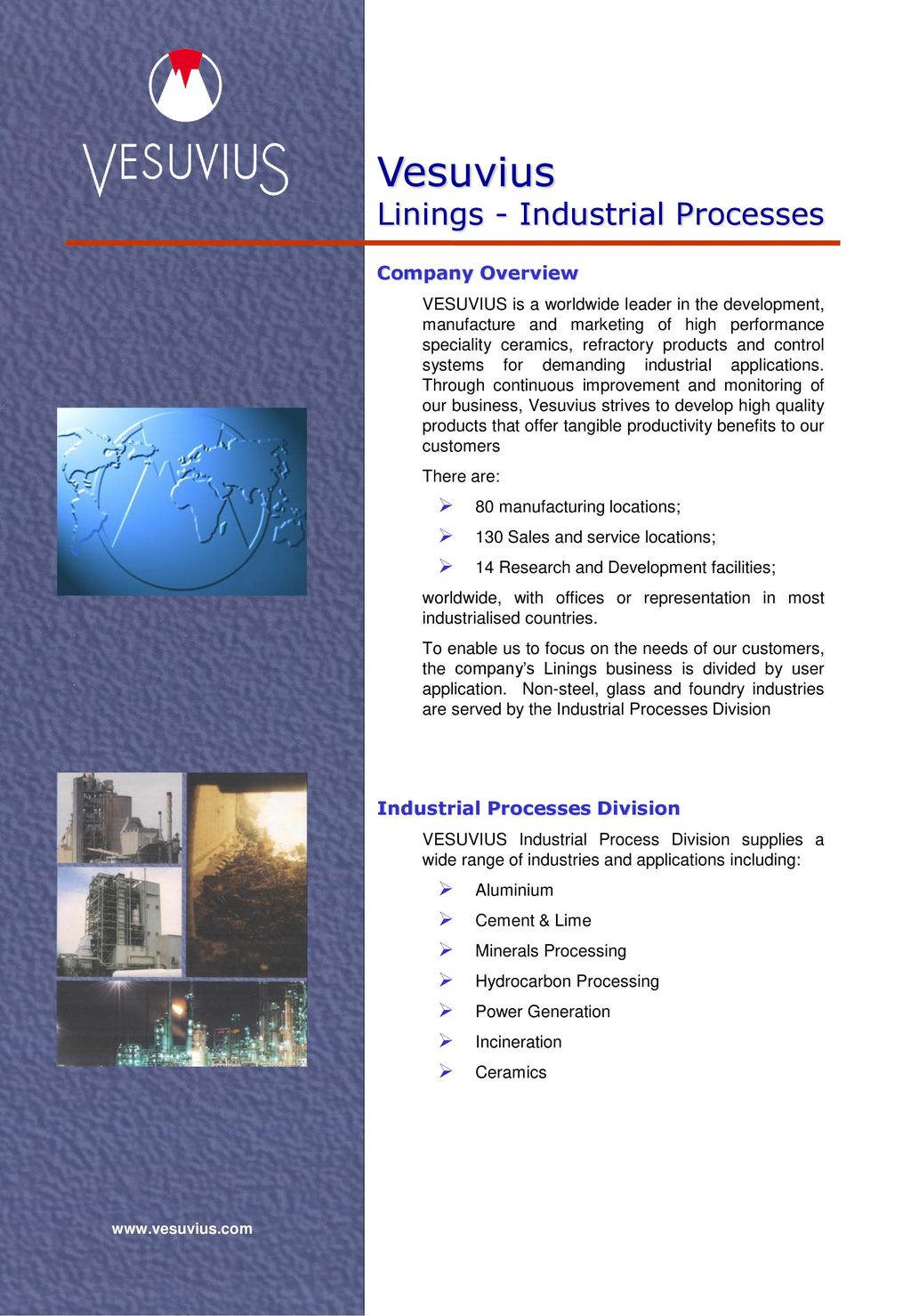

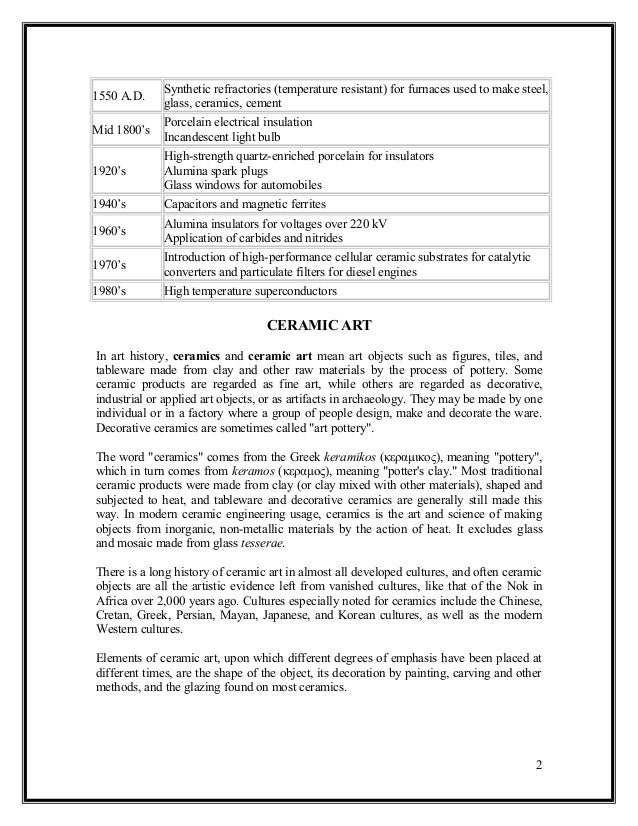

Ceramics and refractories ppt. To check whether the refractory can be used at the particular servicing temperature. These refractories created the necessary conditions for melting metals and glass on an industrial scale as well as for the manufacture of coke cement chemicals and ceramics. When synthetic materials with better resistance to high temperatures called refractories were developed in the 16 th century the industrial revolution was born. Refractories industrial ceramics refractory is a material that will retain its shape and chemical identity when subjected to high temperatures and is used in applications that require extreme resistance to heat such as furnace linings.

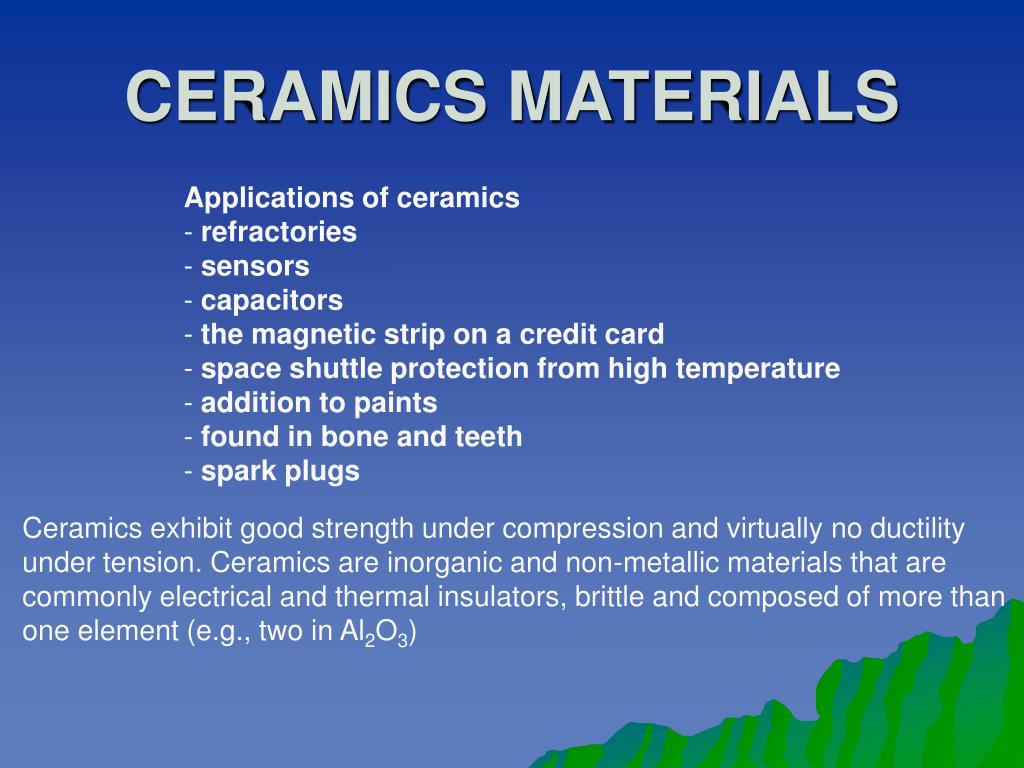

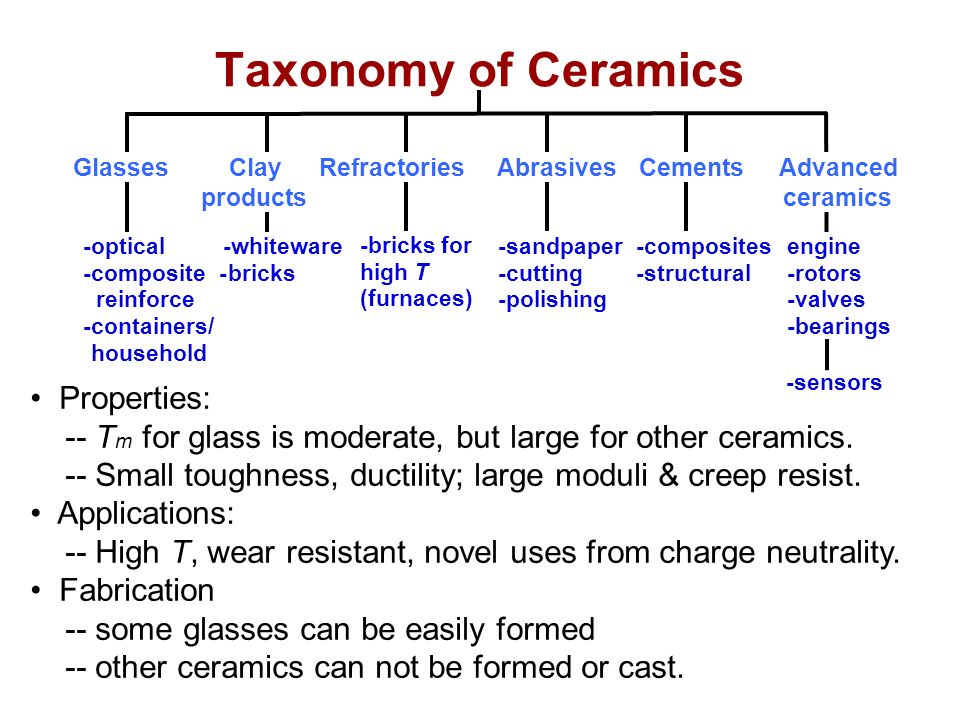

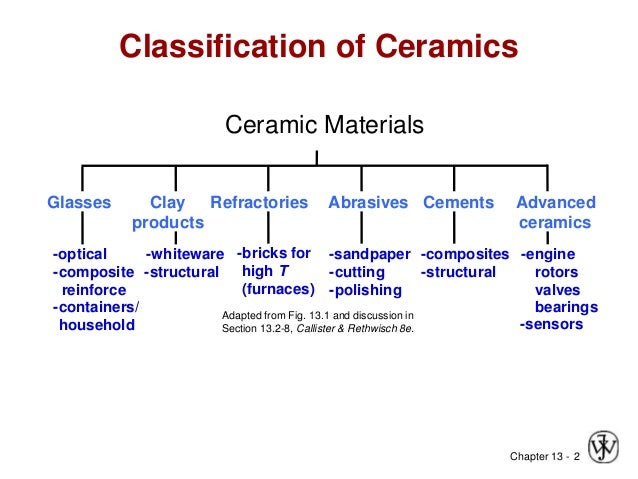

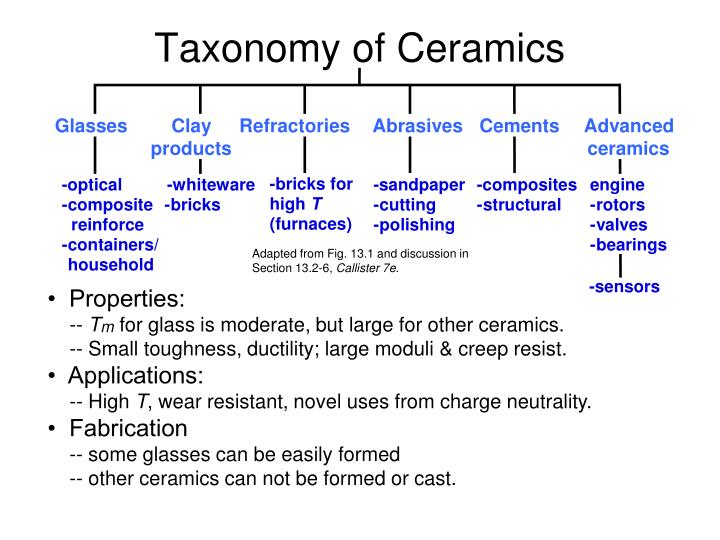

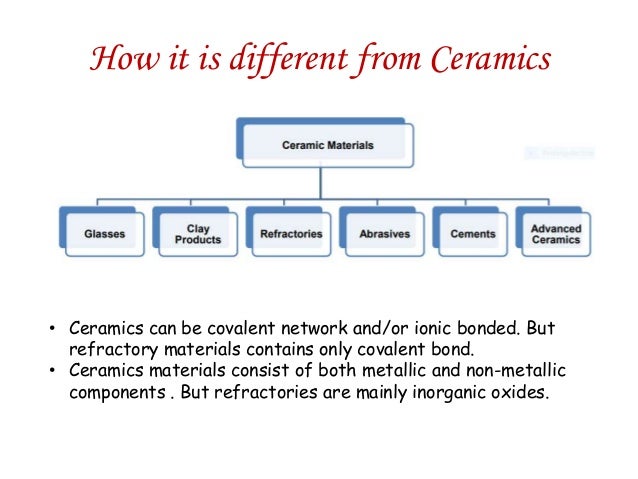

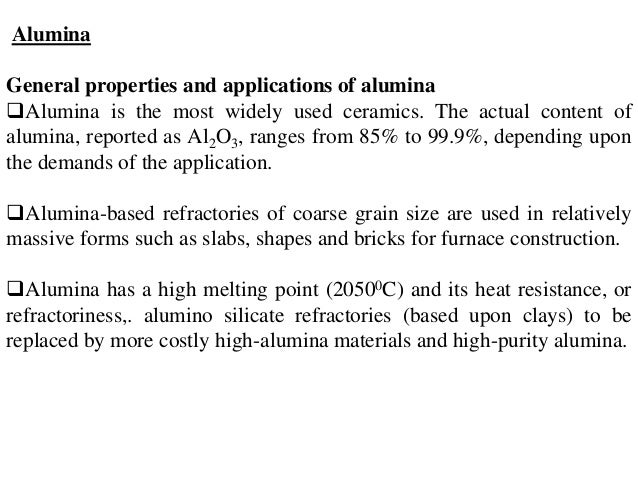

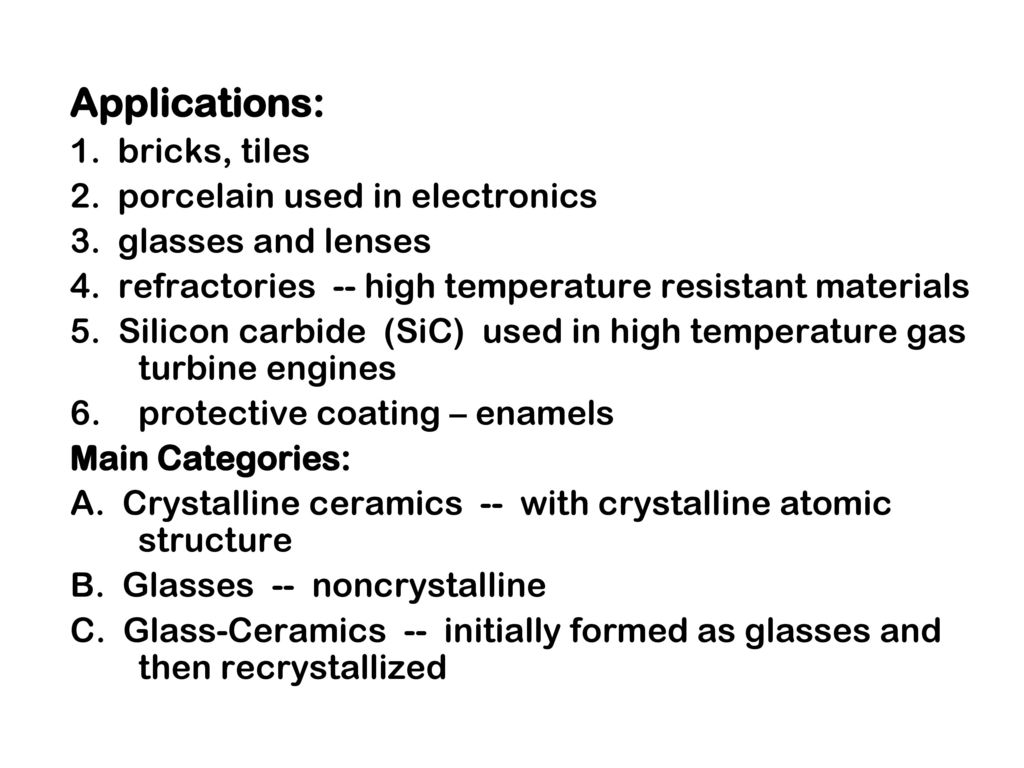

The bi monthly journal refractories and industrial ceramics publishes peer reviewed articles on the latest developments and discoveries in the field of refractory materials and ceramics focusing on the practical aspects of their production and use. Refractory ceramics ceramics capable of high temperature applications such as furnace walls crucibles and molds cement used in concrete used for construction and roads whiteware products pottery stoneware fine china porcelain and other tableware based on mixtures of clay and other minerals. O the clay in traditional ceramics provides workability of the material before firing hardens it and constitutes the major body material. Global ceramic fiber market insights forecast to 2026 free research report pdf.

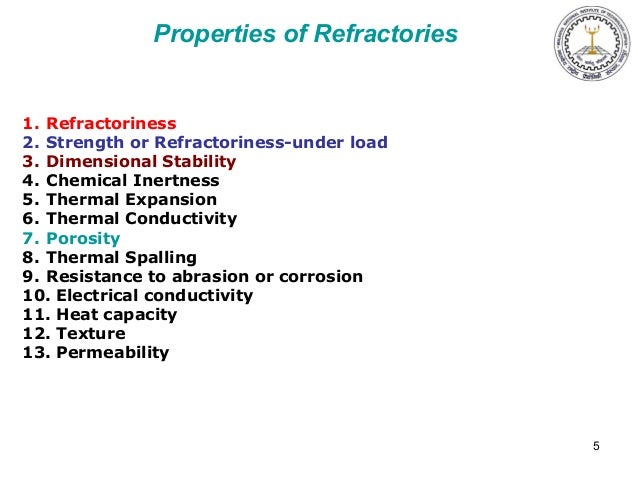

Clay silica flint and feldspar. Heat engineering and applications. To determine the purity of refractories. Why pce test 2 porosity the porosity of a material is a measurement of how much of its volume is open space also called pore space.

Test is performed by applying a constant load of 3 5 or 1 75 kg cm2 to the refractory specimen of size 5 cm2 and 75 cm high and heating in a carbon resistance furnaces at a standard rate of 10 c min. Https bit ly 2x3blzg ceramic fiber is a fibrous refractory material a light weight high temperature good thermal stability low thermal conductivity specific heat of small and resistance to mechanical shock etc luyang energy saving materials morgan thermal ceramics and unifrax captured the top three. Ceramics and refractories cover a wide range of fields and applications and their relevance can be traced as far back as 24 000 bc to the first man made piece of earthenware and as recently as the late 1900s when ceramics and ceramic matrix composites were developed to withstand ultra high temperatures. Traditional ceramics made from three basic components.

Refractories and industrial ceramics publishes peer reviewed articles on the latest developments and discoveries in the field of refractory materials and ceramics focusing on the practical aspects of their production and use. Refractory products are basically used in industries for heat resistant and containment.