Ceramics Stress Of Instantaneous Temperature Change

Factors affecting thermal stress resistance of ceramic materials by w.

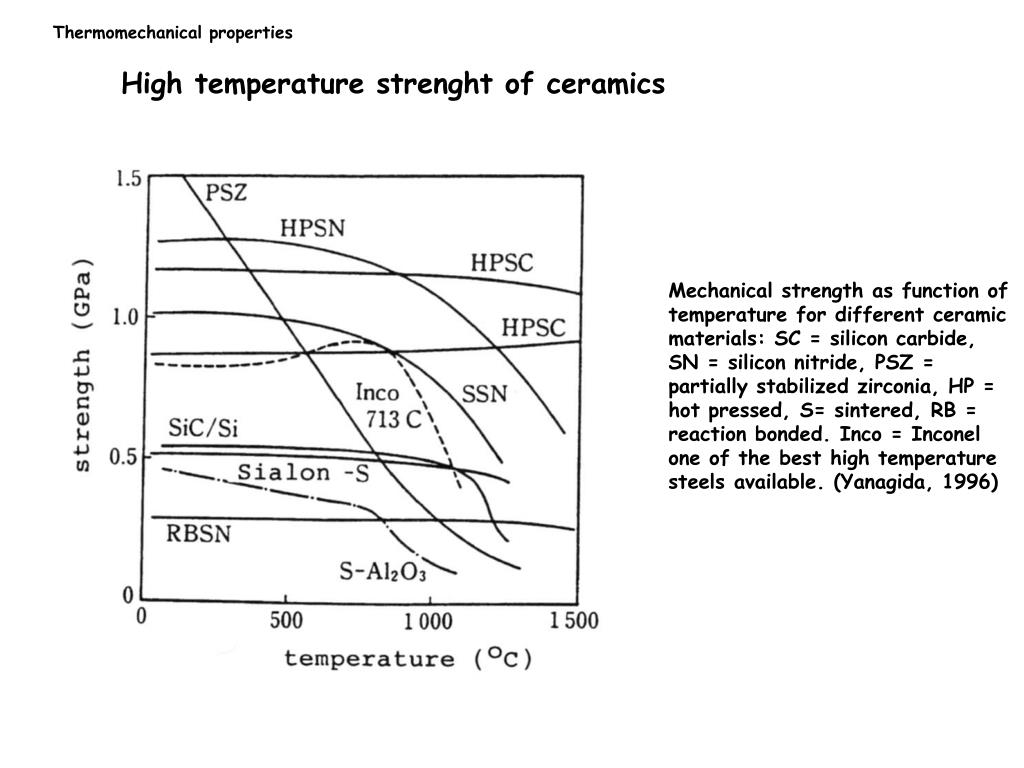

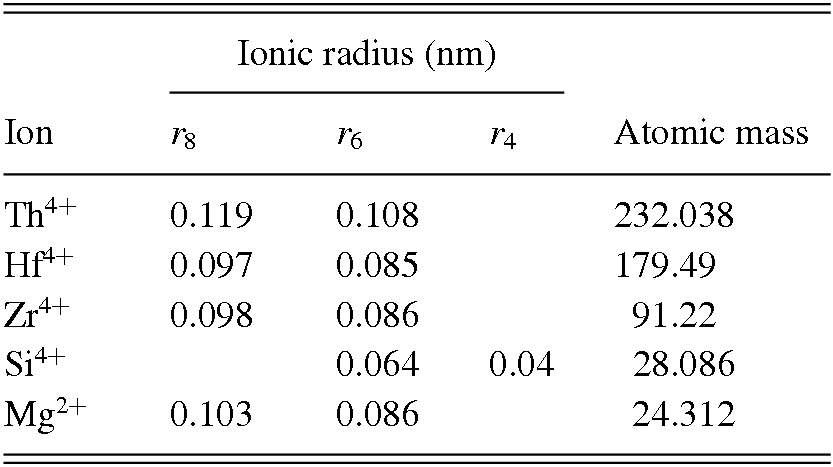

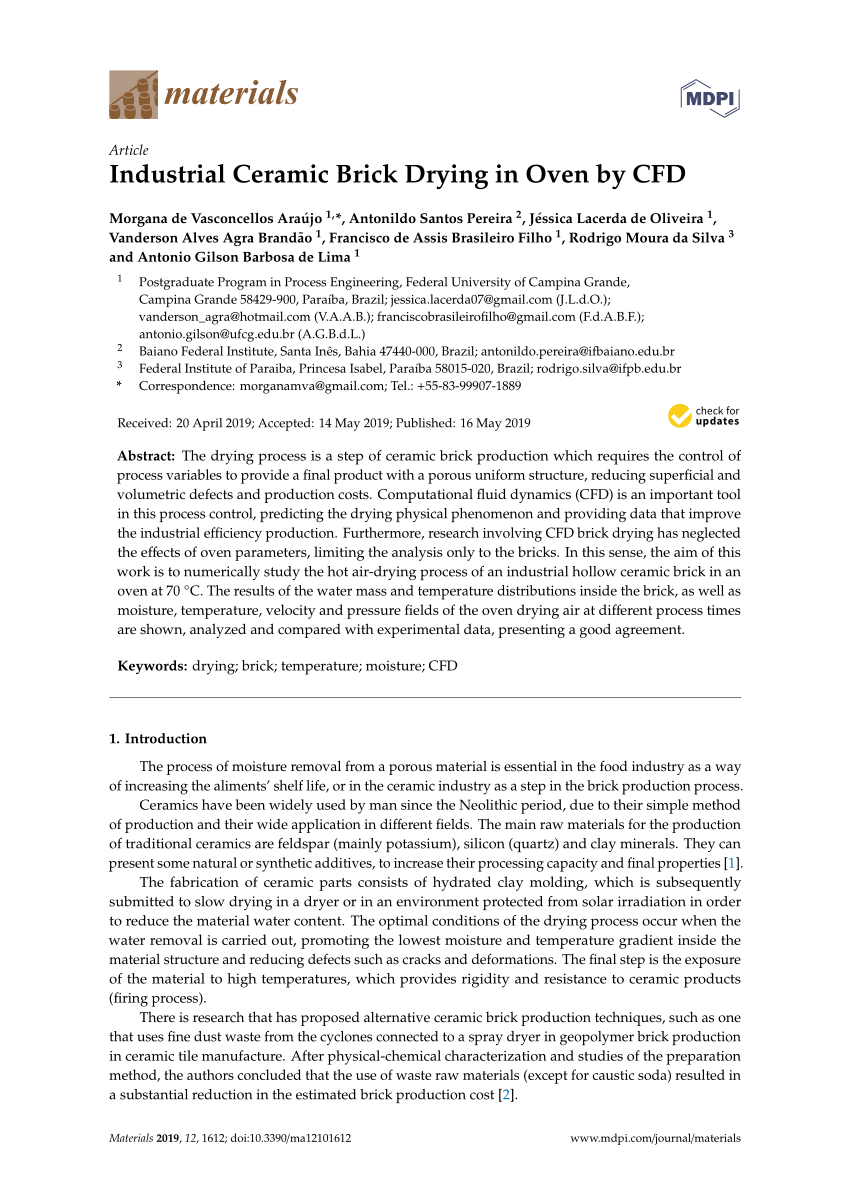

Ceramics stress of instantaneous temperature change. Materials science and engineering 71 1985 251 264 251 thermal stress resistance of engineering ceramics d. In mechanics and thermodynamics thermal stress is mechanical stress created by any change in temperature of a material. Polycrystalline materials are formed by multiple. Generally strength and modulus go up and down together.

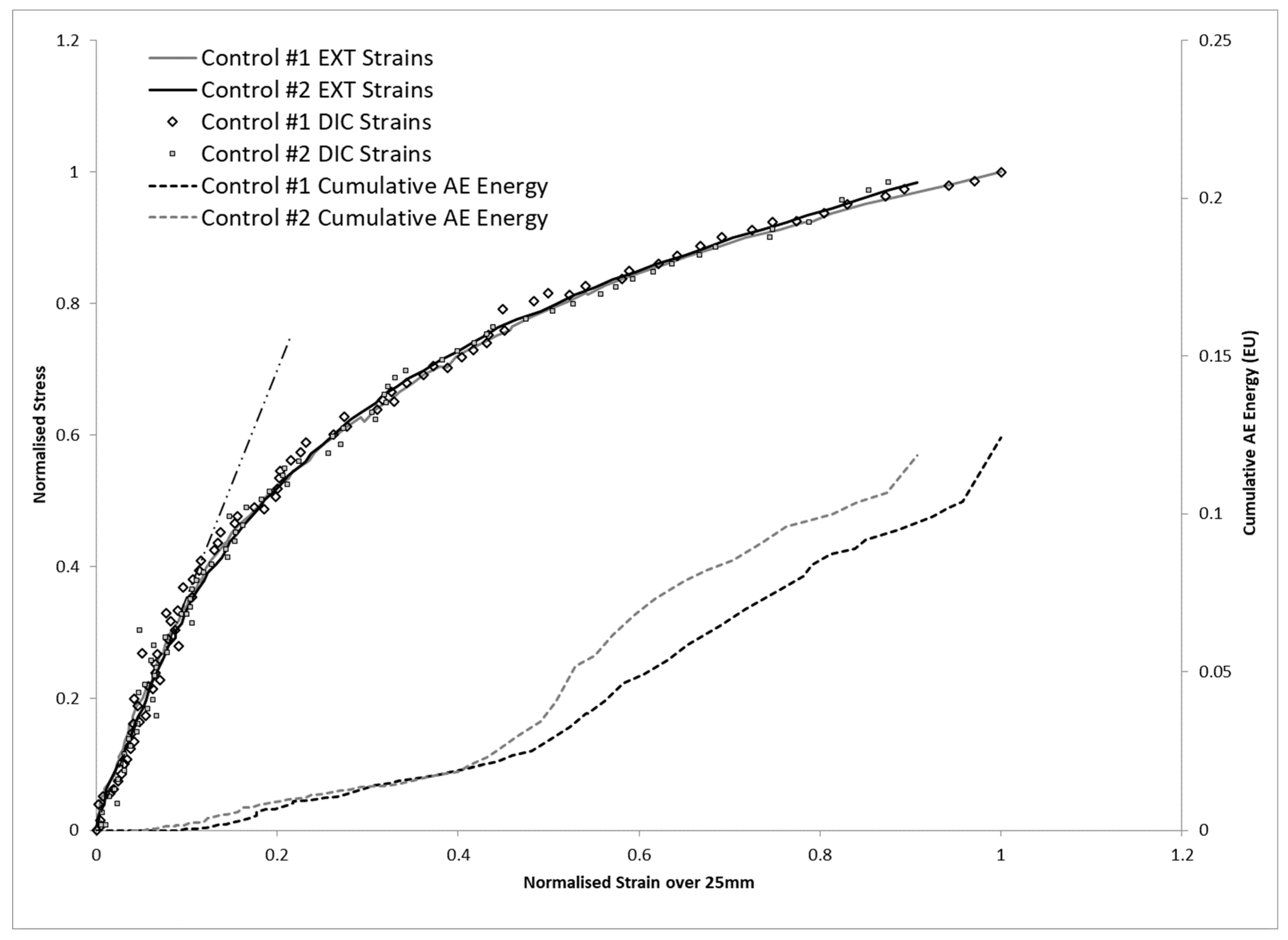

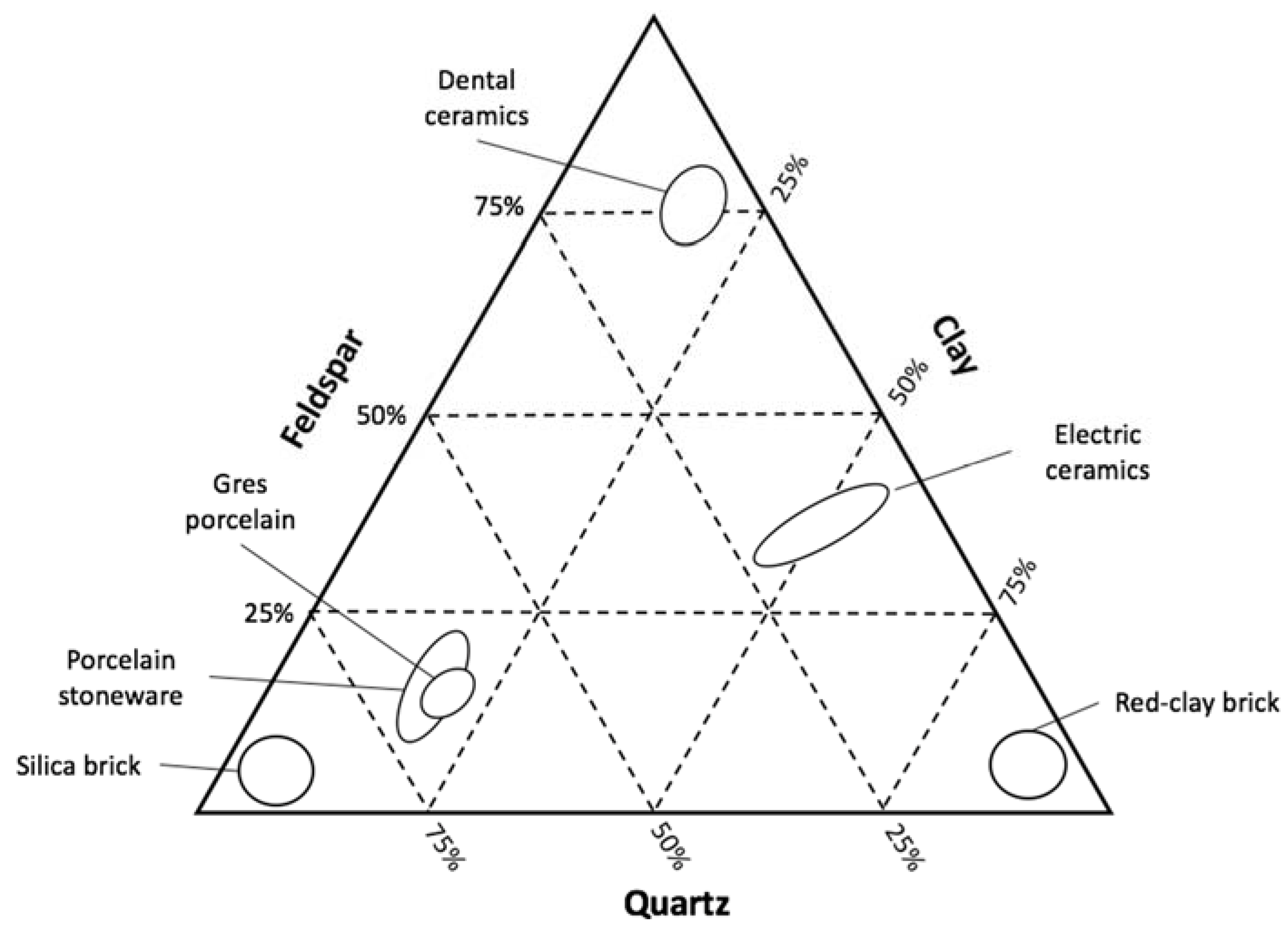

Ceramics are by definition natural or synthetic inorganic non metallic polycrystalline materials. Quenching polymer concentration method were all 500 c s 1 i e. σ dt e ε e dl l o e α l o dt l o e α dt 4 where. When restricted expansion is converted to stress then 1 2 and 3 can be combined to.

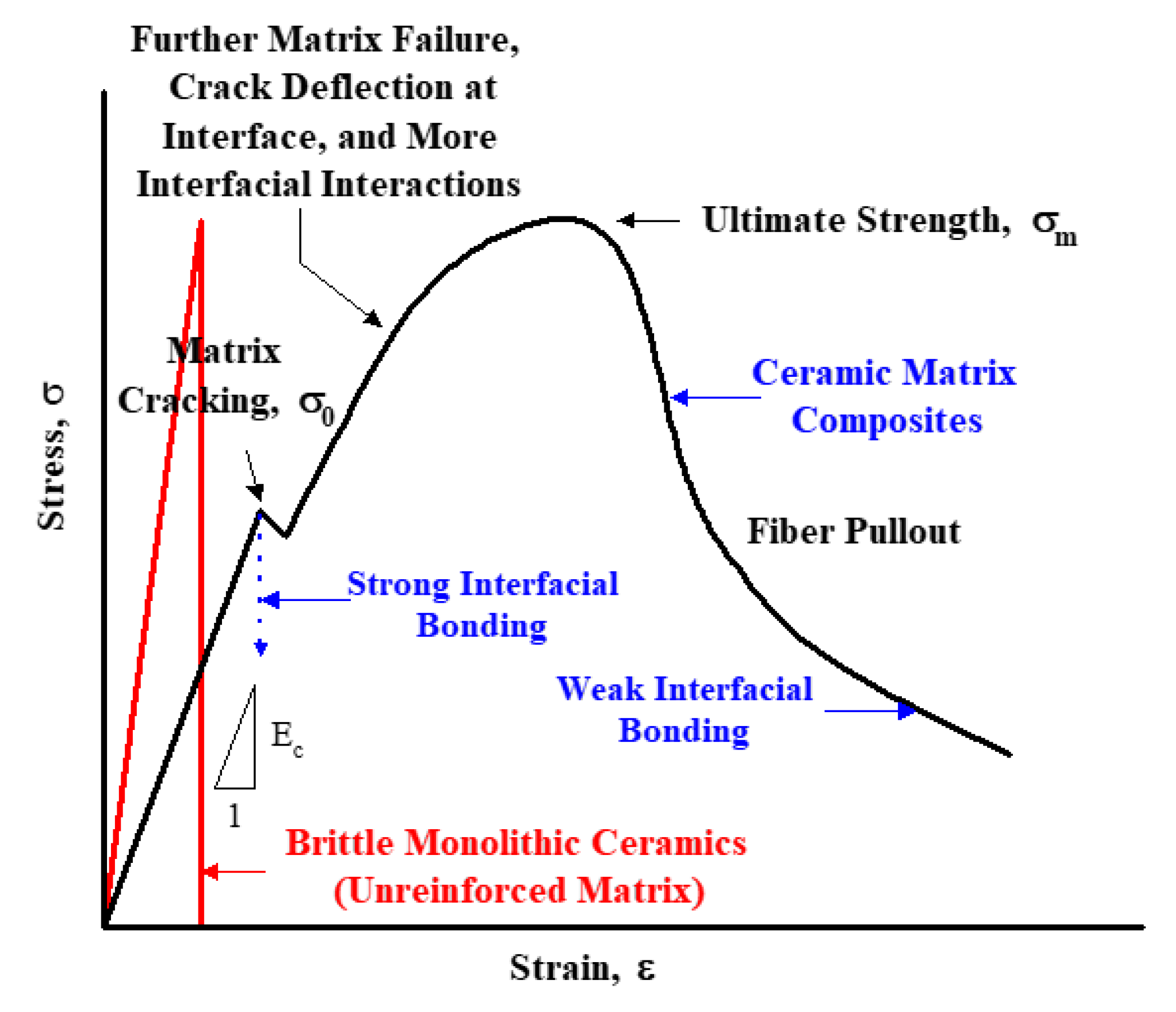

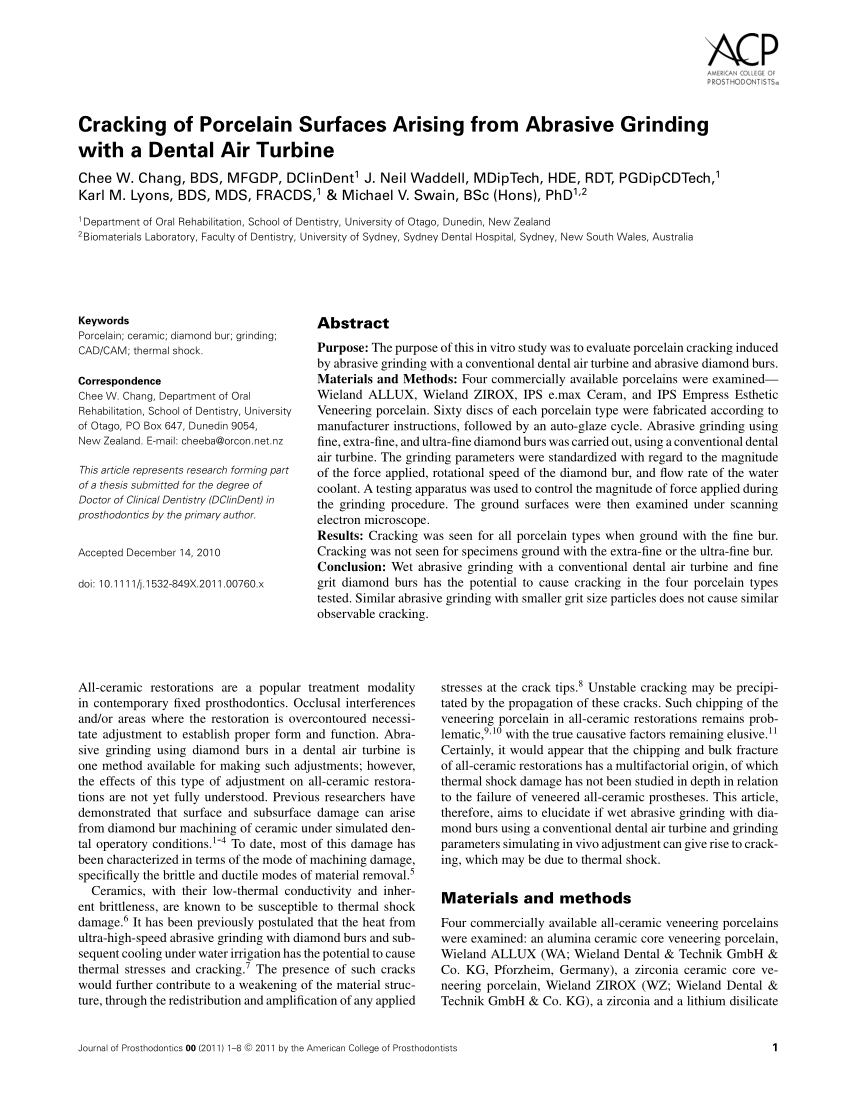

These stresses can lead to fracturing or plastic deformation depending on the other variables of heating which include material types and constraints. Ceramics 30 350 gpa metals 50 200 gpa polymers 50 gpa 2. Plane strain conditions give the lowest. Hasselman department of materials engineering virginia polytechnic institute and state university blacksburg va 24061 u s a received october 7 1984 abstract an overview is presented of the current understanding of the variables which affect the thermal stress failure of.

Request pdf an aqueous polymer quenching medium for instantaneous thermal shock cooling rate study of ceramic materials an aqueous polymer quenching technique combing with a thermocouple real. Sometimes even monocrystalline materials such as diamond and sapphire are erroneously included under the term ceramics. Kingery ceramics division department of metallurgy massachusetts lnstihrte of technology cambridge massachusetts the sources and calculation of thermal stresses are considered together with the factors in volved in thermal stress resistance factors. The maximum permitted instantaneous temperature gradient generated during aqueous silicone oil quenching condition should not exceed 500 c s 1.

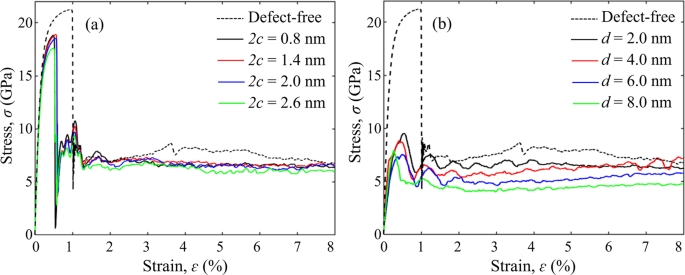

σ dt stress due to change in temperature pa n m 2 psi axial force. The experimental ν max c measured at three heating temperature 500 c 600 c 700 c using residual strength vs. Properties depend both on temperature and degree of crystallinity. In materials science fracture toughness is the critical stress intensity factor of a sharp crack where propagation of the crack suddenly becomes rapid and unlimited.

A component s thickness affects the constraint conditions at the tip of a crack with thin components having plane stress conditions and thick components having plane strain conditions. Modulus e at 25c linearly related to melting temperature tm. Properties affecting thermal stress resistance of. Mechanical properties versus melting temperature.

The axial force acted by the restricted bar due to change in temperature can be expressed as.