Ceramics Tubes Inc Llc

Coorstek manufactures thousands of engineered ceramic components and products.

Ceramics tubes inc llc. Also for temperature measurement or as burner holes in gas and oil fired kilns. Tube extrusion is valued for its ability to produce uniform goods its high efficiency and the ability of extrusion equipment to run continuously. Ceramic tubes may be fabricated in a number of ways however the most widely used method of ceramic tube fabrication is extrusion. The tubes are normally supplied as dense mullite em60 or alumina ea998 for these applications.

Choose from our selection of ceramic tubing including over 90 products in a wide range of styles and sizes. Most items are in stock and can be pulled and shipped normally under 1 week aro. Configured with alumina or silicate ceramics these are accessible as multi bore tubes for utilization as resister thermometers or resistor temperature sensors. We offer a number of advanced ceramic products including custom ceramic parts or standard products like our ceramic tubes and rods.

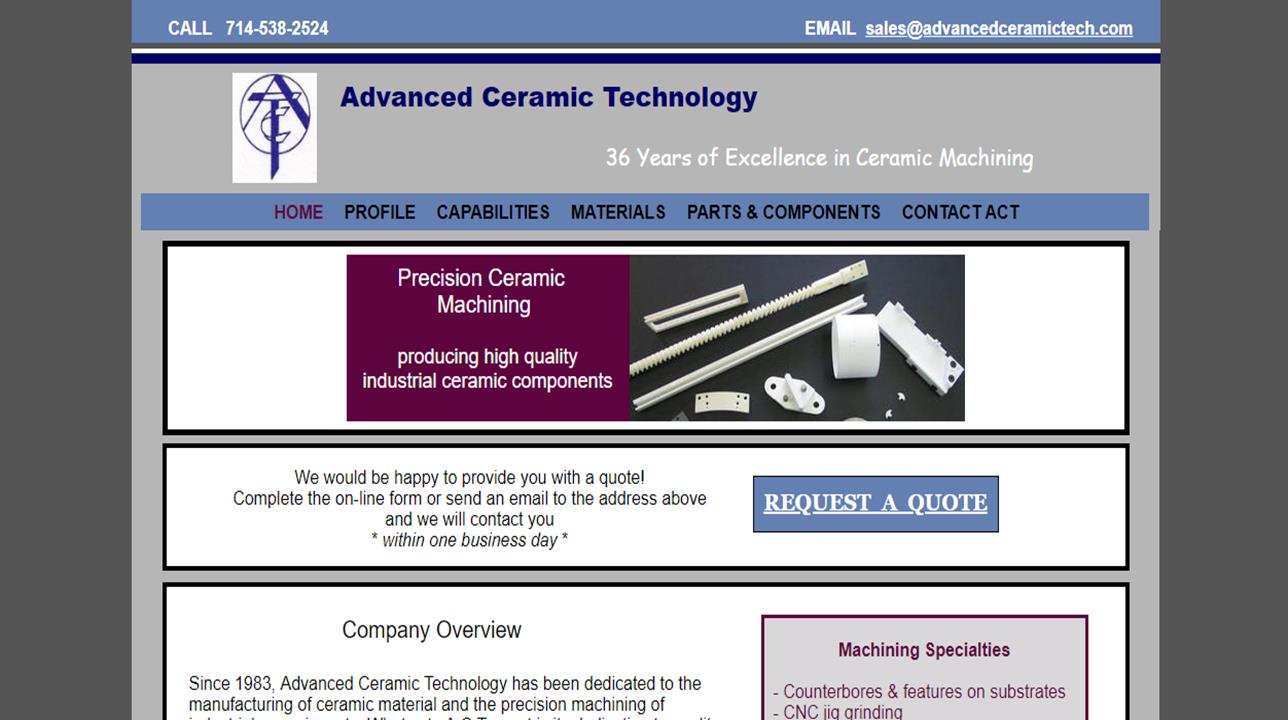

In stock and ready to ship. Because of our core focus on ceramic technologies mcdanel is uniquely positioned to provide you with superior products and dedicated service for an unparalleled range of applications. Alumina can take temperatures up to 1650 c having extremely high temperature stability chemical corrosion resistance and high wear and abrasion resistance. Alumina tubes for high temperature furnaces.

Ceramic tubes are ideal to provide lead outs for electrical cables. Mcdanel advanced ceramic technologies llc is a leader in developing and manufacturing the highest quality ceramic tubes and ceramic components. Browse our alphabetical product listing. International ceramic engineering manufactures alumina tubes as a standard ceramic product.

Alumina tubes come in custom sizes including american and metric and offer a low material cost. Coorstek offers a wide variety of tubes and rods manufactured from high performance technical ceramic materials including alumina zirconia and silicon carbide. Ceramic tubes are utilized to make temperature measurement as well as control devices. Porous ceramic tubes are also used to support wound elements for heating larger furnaces and kilns.

Enhance performance and product life by using the material best suited to your application.