Ceramics Used In Cars

What properties do ceramics have.

Ceramics used in cars. That bond is permanent as the paint and the polymer become one layer that is tougher. Picture by warren gretz courtesy of us department of energy national renewable energy laboratory nrel picture id 6307388. Ceramics are more cost efficient than metal and more durable than plastic and can be found throughout the automotive industry as advances in car manufacturing require higher complexity in automotive components. Ballistic door panels are integrated in the body of police cars and other high security vehicles.

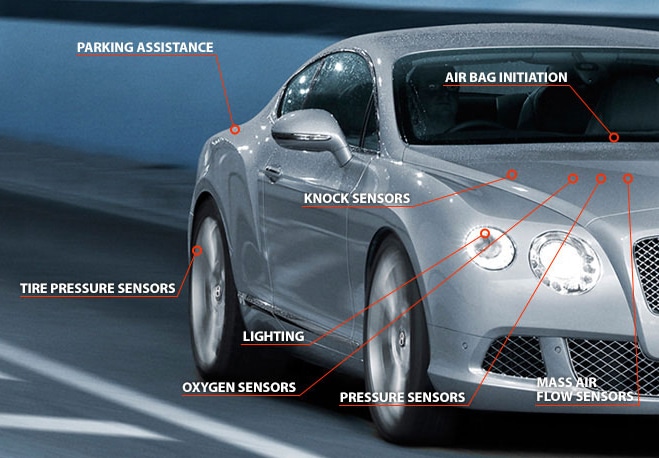

Spark plugs passive components and low temperature co fired ceramics ltccs are the most relevant ceramic elements found in the electrical electronic system. Examples include spark plug insulators catalysts and catalyst supports for emission control devices and sensors of various kinds. Epoxy or polymer is a widely used type of ceramic coating that bonds with the factory paint coating of the car. 32institute for applied materials ceramics in mechanical engineering the increasing efficiency of fuel saving cars requires a supplementary heat system based on functional ceramics showing a positive temperature coefficient resistance ptcr effect.

Ceramic components are also used in ordinary car engines for the same reason.