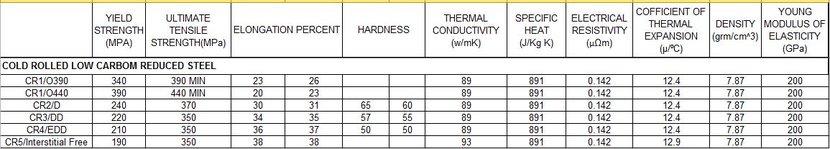

Cold Rolled Sheet Metal Properties

Cold rolled steel is essentially hot rolled steel that has been through further processing.

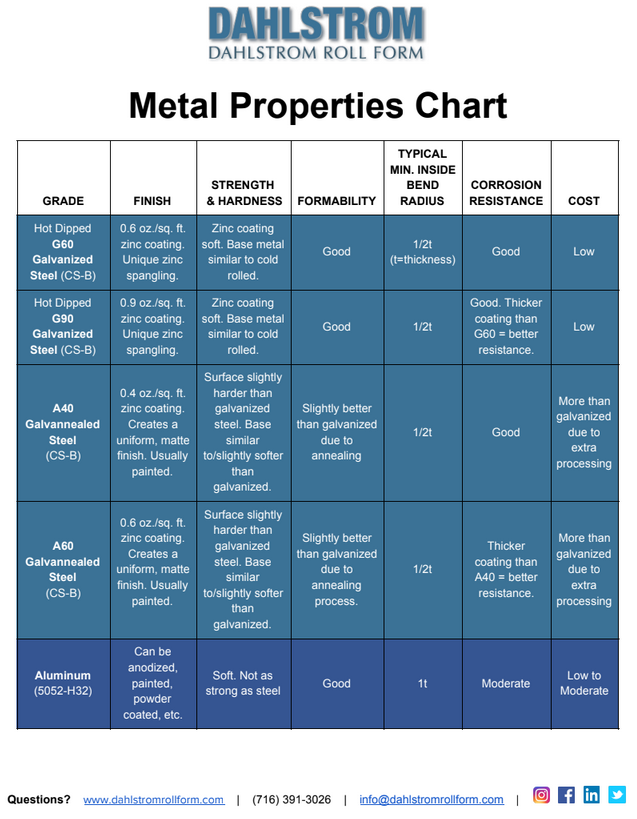

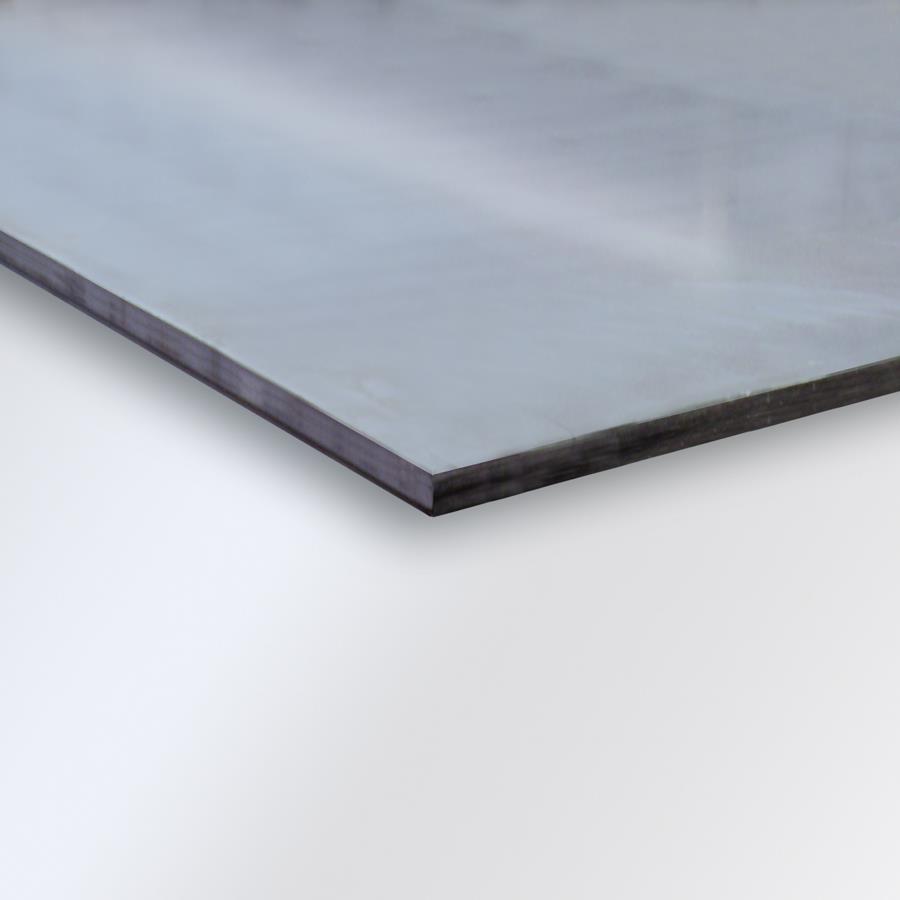

Cold rolled sheet metal properties. Hillman 6 in x 18 in cold rolled steel solid sheet metal. Therefore cold rolled steel is identifiable by an oily and smooth surface. Cold rolled commercial quality sheet or coil steel supplied for either exposed or unexposed applications where bending welding forming or moderate drawing is involved. Thus the yield strength of cold rolled steel is higher than that of hot rolled steel.

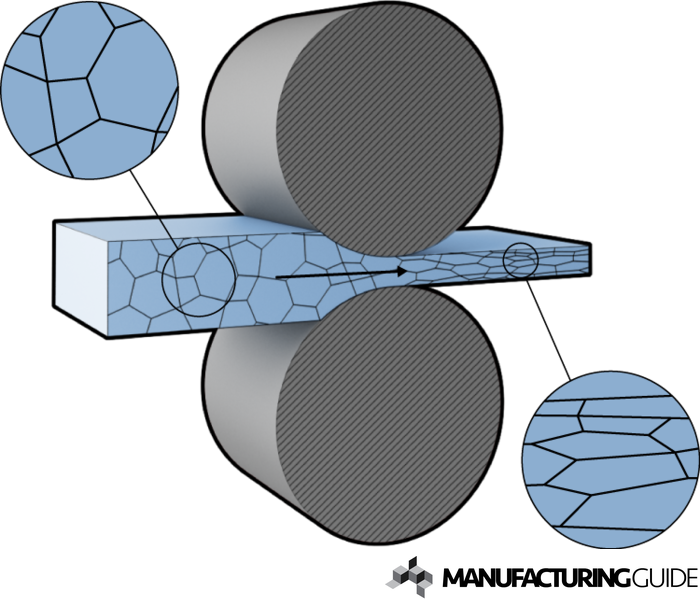

Once hot rolled steel has cooled it is then re rolled at room temperature to achieve more exact dimensions and better surface qualities. The thickness of the hot rolled strip is important in that the properties of the final cold rolled and annealed product is influenced by the percent of cold reduction. Here are the physical and chemical properties of the 1008 1010 carbon steel that we regularly stock. Commercial steel ds types a b and c.

Hillman 12 in x 18 in cold rolled steel solid sheet metal. Cold rolled steel cold worked steels are typically harder and stronger than standard hot rolled steels. Cold rolled has sharper corners and more precise dimensions than hot rolled. Cold rolled 1008 1010 steel physical properties astm a1008 1010.

As the working takes place in temperatures below the rescrystallisation temperature strain hardening occurs. Cold rolled is more expensive than hot rolled. In general cold rolled steel sheet can hold tighter tolerances than hot rolled when machined or otherwise fabricated and provides a better overall surface finish. When steel is formed by press braking or cold rolled forming there is a change in the mechanical properties of the material by virtue of the cold working of the metal.

Cold roll our large cold roll steel stock is available in various shapes and alloys with full sizes available. For pricing and availability. When a steel section is cold formed from flat sheet or strip the yield strength and to a lesser extent the ultimate strength are increased as a result of this cold working particularly in the bends of the section. Get a fast quote.

Cold rolled has a smooth and shiny finish while hot rolled has a grey and scaly finish. Buy online or contact us for a quote. The rolls induce plastic deformation. No cut fees no minimums and fast delivery or online order pickup from 6 warehouses nationwide.

This means that the thickness of each hot rolled coil is carefully controlled to provide the mill with a specific thickness to achieve the proper percent cold reduction.

.jpg)