Conductive Aluminum Paste Solar Panels

The solar imb laminate plus sg7115 aluminum foil sc7135 laminate also increases the metal moisture barrier contributing to the long term reliability of the thin film solar panel.

Conductive aluminum paste solar panels. Compared to copper which many people associate with electrical wiring because of its conductivity aluminum has 59 the conductivity while having only 30 the density. How much silver gets used in a solar panel. Silver paste and aluminum paste is commonly used to form contact. Aluminum wiring was actually first used in the early 1900s and its.

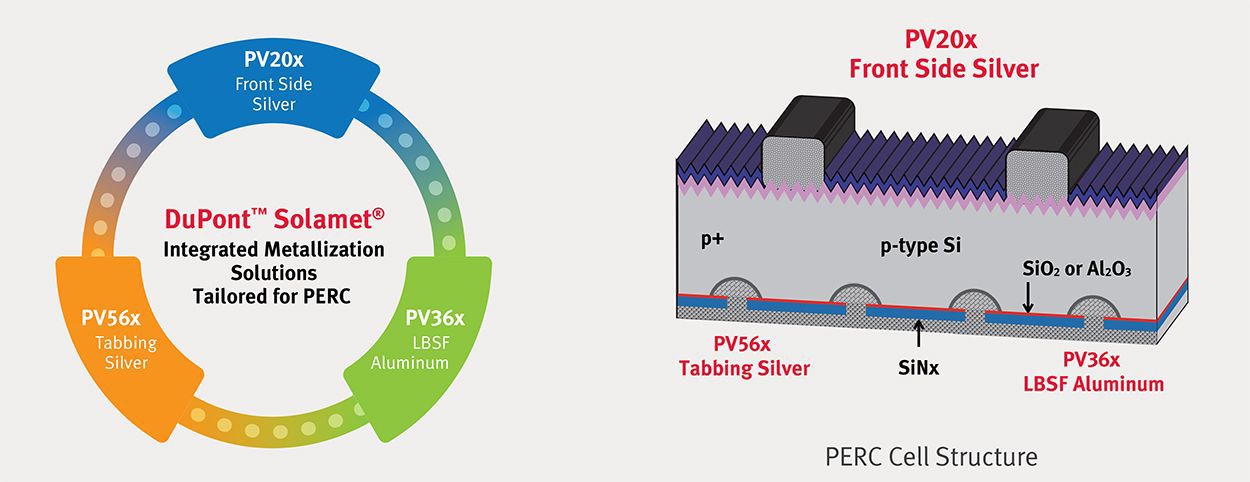

Uniform bsf and strong adhesion to the si wafer yield a combined efficiency gain of approximately 0 1 higher than other commercially available al paste. In silicon solar cells forming good ohmic contact between the emitter and the metal with minimum contact resistance is critical to achieve peak electrical performance. The current silver use cost per solar panel is around 6 1 of the total cost of the price of building each solar fuel cell unit. Factors related to paste chemistry process conditions and the solar cell wafers influence the contact quality.

Transparent conductive oxides tco are doped metal oxides used in optoelectronic devices such as flat panel displays and photovoltaics including inorganic devices organic devices and dye sensitized solar cells most of these films are fabricated with polycrystalline or amorphous microstructures. Our rear side conductive aluminum paste enables solar cell makers to create a uniform high quality back surface field bsf for their mono and multi crystalline solar photovoltaic cells. In addition to demanding precise alignment of the patterning system multiple printing requires the paste to be finely tuned to perform consistently during all printing passes. Average solar panels are about 1 8 square meters in size and use about 20 grams or 0 643 troy ounces of physical silver.

That makes aluminum a great choice when it comes to electrical applications. The top countries of supplier is united states from which the percentage of solar conductive aluminum paste supply is 1 respectively. The amount of silver needed to produce conductive silver paste for the front and back of most pv cells may be almost halved from an average of 130 mg per cell in 2016 to approximately 65 mg by. Typically these applications use electrode materials that have greater than 80.

To maximize the efficiency of a solar cell double or multiple printing technology reduces the shadowing effect of wide grid lines and improves electrical conductivity. Solar tdb is a single ply of sg7115 sg7135 melt encapsulation sheet to provide good thermal dissipative capability and more than 1500v insulation.

.jpg)