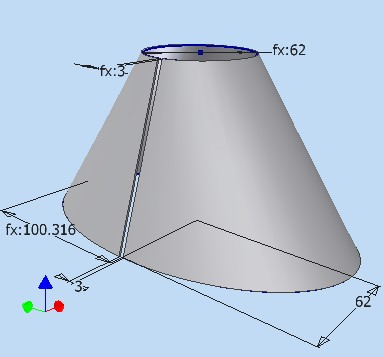

Cone Inventor Sheet Metal

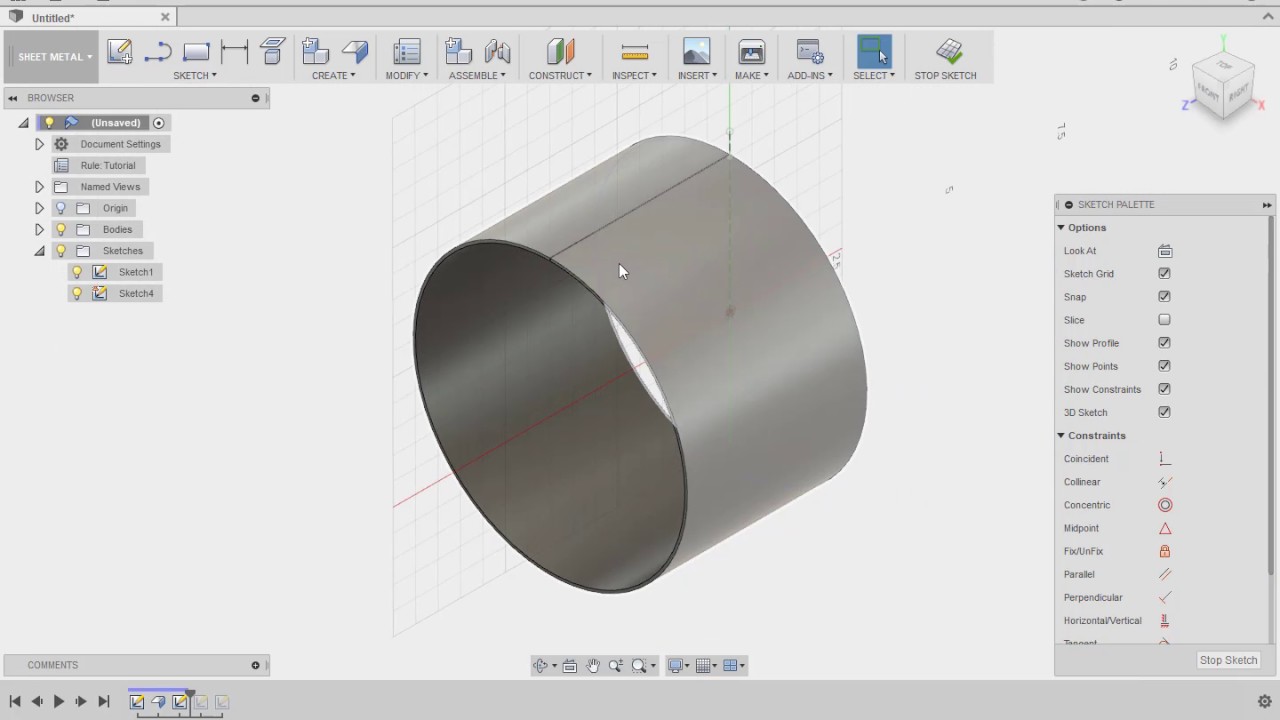

Set the sheet thickness and default bend radius.

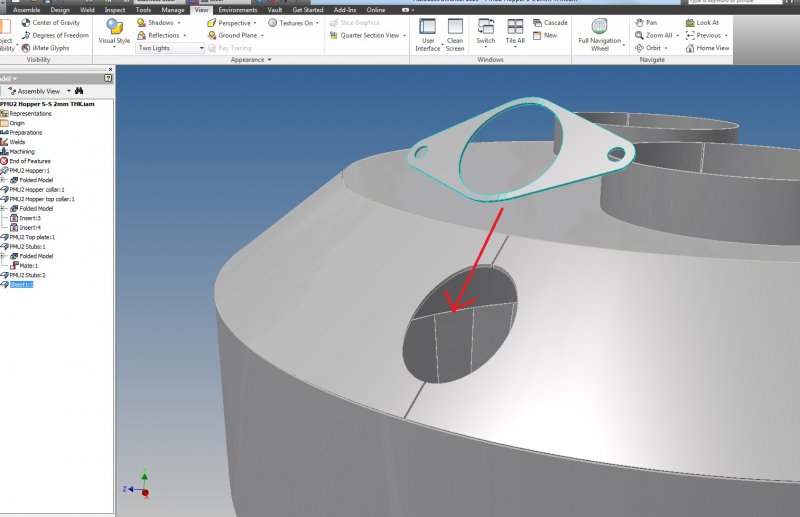

Cone inventor sheet metal. Sheet metal design software considers the fabrication methods needed for manufacturing. Understanding the rules for inventor sheet metal opens up the entire toolbox of tools rather than limiting the user to those tools designated as sheet metal. As you create flanges and add bends the sheet metal design software will accurately represent the flat pattern required. Select keep body if you want to keep the solid body to use in another convert to sheet metal feature.

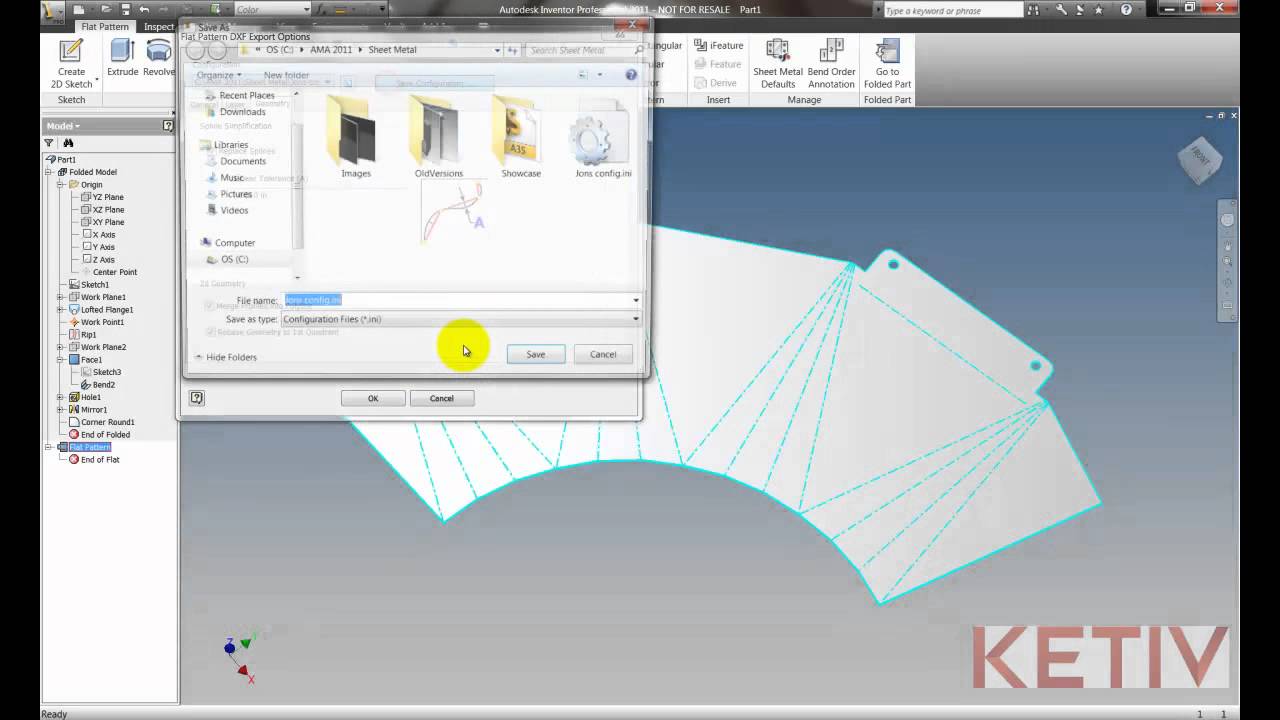

The flat pattern can be used to document and manufacture associatively as the design changes. The curved steel cone calculator from chicago metal rolled products makes it easy to find the precise curved steel cone dimensions you need. The layout may either be done on the material. Use all of the tools in your inventor toolbox to create the geometry you need.

View the cone instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. Sheet metal lofted flange dialog box creates a shape between two sketched profiles. It allows you to determine either the size of raw material needed or the number of gore sections to fit on your available material. Sheet metal bend zone edit reference edits the bend radius and unfold rule for a bend within a specified bend zone of a lofted flange.

When cleared the body is consumed by the convert to sheet metal feature. When flattened this creates a swept angle measured between the flat cut ends of the plate of more than 180 degrees. Select a face as the fixed face for the sheet metal part. Under sheet metal parameters.

In the example shown in the 2 videos the included angle is around 76 degrees and the flat part swept angle is around 222 degrees. Uniform thickness planar faces connected with cylindrical or conic bends br non intersecting faces in folded or. Sheet metal cone calculator.